Dust removal mechanism of bag filter

2025-05-16

The principle of filter bag dust clean in bag filtration system:

1. Overall principle

Dust-containing gas flow through the fibre layer, due to the size of the dust contained in the gas is often much smaller than the pore space in the filter layer, so the effect of removing dust through the sieve effect is very small. Dust can be separated from the gas stream, mainly retention, inertial collision and diffusion effects; followed by gravity and electrostatic force of a certain role.

① retention: with the flow of particles with the flow, due to direct contact with the capture group and be retained.

② inertial collision: particles due to inertia and capture the collective collision and capture.

③ Diffusion: tiny particles in the gas molecules under the impact, like gas molecules for Brownian motion, if the particles in the process of movement with the surface of the catching group contact, it will be adhered to the surface of the catching group.

Gravity: the larger particles rely on gravity to settle naturally and separate from the gas flow.

⑤ electrostatic force: charged particles and (or) fibres produce electrostatic force of attraction between the particles through the electrostatic force of attraction so that the particles are adsorbed in the catch group (fibre), separated from the airflow.

2. Woven filter media and non-woven use of the initial dust removal mechanism

The use of filter media dust removal, the initial dust removal mechanism, for woven fabrics and non-woven fabrics are different. Woven fabric dust removal process is, first of all, dust particles in the cloth within the aperture bridging the formation of dust layer, and then dust removal efficiency rises; and non-woven fabrics and air purifiers are similar to the dust particles not only can be attached to the fibre (rod) on the formation of a dust layer, but also can be immersed in the interior of the filter media, there is a tendency to filter the interior. Therefore, it can be considered that the filter media dust removal in the early stage, the main role of the dust removal mechanism is inertial collision, diffusion and retention, in addition, electrostatic force and gravity also have a role. During this period of dust removal efficiency of about 50 per cent to 80 per cent.

For woven fabrics, when its pore size is more than 10 times larger than the dust particles, it is generally believed that its initial dust removal performance is not good.

Dust from the bag filter inlet into the dust, due to the lower hopper in the lower flow rate and impact on the baffle, coarse dust can be separated from the airflow to settle out. By the time it reaches the filter media, the dust concentration may be reduced by half compared to the inlet. This means that only fine dust can accumulate on the filter media. The dust load on the filter media is reduced, but the fine particles tend to clog the pores of the filter media and increase its pressure loss. However, it is difficult to measure the dust load of pure filter media on the dust collector in use.

3. Dust removal mechanism and dust removal efficiency during normal use of filter media

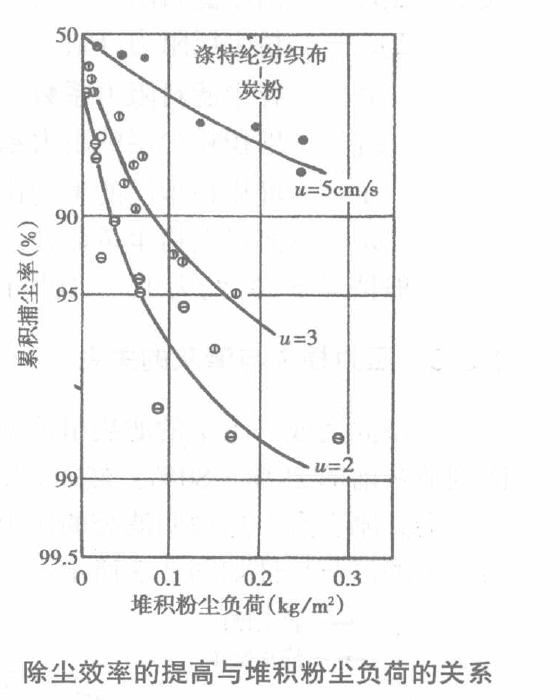

When dust-containing gases pass through the filter media, as they penetrate deep into the interior of the filter media, the fibre space is gradually reduced, and eventually a dust layer (called the initial layer) is formed which is attached to the surface of the filter media. Bag filter in addition to the initial dust removal, mainly relying on the initial layer and later gradually accumulated dust layer to remove dust. The level of dust removal efficiency is mainly determined by the dust has been captured in the second flight. If the dust layer has an optimum thickness, it is not only for coarse particles (more than 1μm) but also for fine particles (less than 1μm) can be well captured, and the lower the filtration wind speed the better. As the dust layer becomes thicker, the straight-through phenomenon decreases, but the press-out and porosity phenomena tend to increase. Figure 1 shows the relationship between dust load and dust removal efficiency under different filter speed conditions. From the point of view of improving the dust removal performance, selecting a low filter air speed is conducive to improving the dust removal efficiency.

Bag filter is a dust removal device developed through practice, its technical characteristics by the filter media structure, dust particles, fluid parameters and physical and chemical properties of the gas and many other factors. Although the characteristics of the filter media parameters can not be completely through theoretical calculations, but in the grasp of the dust filtering mechanism and dust bag cleaning mechanism based on the necessary tests, supplemented by the necessary test, to grasp and improve the working characteristics of the baghouse dust collector is very necessary.