What Makes Filter Cloth Essential for Industrial Filtration?

2025-09-10

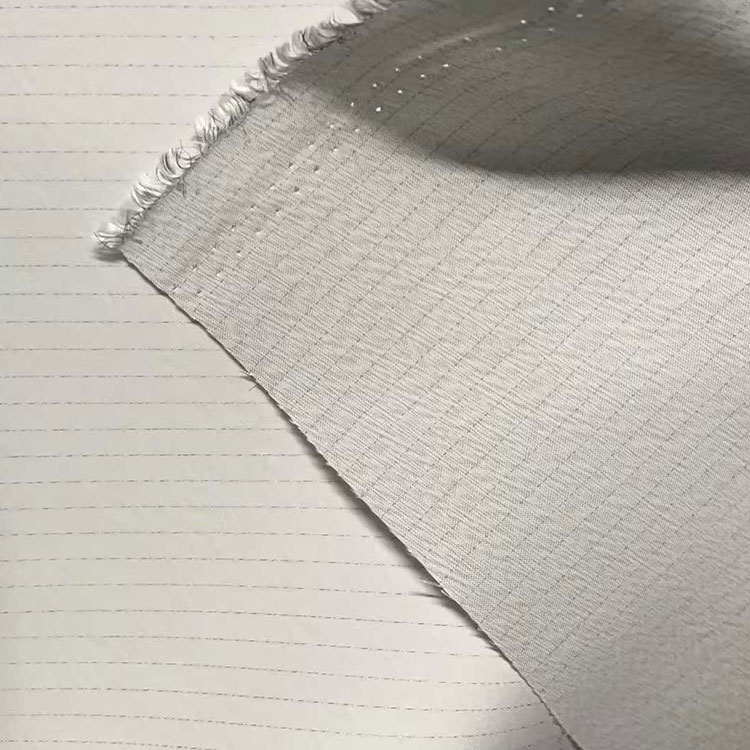

Filter cloth plays a crucial role in modern industrial filtration systems, ensuring the separation of solids from liquids in a wide range of applications. From wastewater treatment and chemical processing to mining and food production, the right filter cloth improves filtration efficiency, reduces operational costs, and enhances product quality. Choosing the correct filter cloth is not just about selecting a material; it requires a deep understanding of its structure, performance, and compatibility with specific processes.

Understanding Filter Cloth and Its Importance

Filter cloth is a specialized woven or non-woven fabric designed to separate solids from liquids during industrial processes. It acts as the primary barrier in filtration equipment such as filter presses, vacuum filters, drum filters, and belt filters. The efficiency of the filtration process largely depends on the quality and characteristics of the filter cloth, making it a vital component in achieving optimal results.

Key Functions of Filter Cloth

-

Solid-Liquid Separation – Traps solid particles while allowing liquids to pass through effectively.

-

Enhanced Filtration Quality – Improves the clarity and purity of filtered liquids.

-

Operational Efficiency – Reduces downtime by enabling faster filtration cycles.

-

Cost Optimization – Extends the life of filtration systems and lowers maintenance expenses.

Applications Across Industries

Filter cloth is used across multiple sectors, including:

-

Water & Wastewater Treatment – Removing suspended solids to meet environmental regulations.

-

Food & Beverage Processing – Ensuring hygiene and purity in sugar refining, brewing, and edible oil filtration.

-

Mining & Minerals – Separating valuable minerals from slurry and managing tailings.

-

Chemical & Pharmaceutical – Handling corrosive liquids and ensuring high-purity outputs.

-

Cement & Power Plants – Managing dust collection and ash handling.

In all these applications, choosing the right filter cloth ensures regulatory compliance, operational stability, and cost-effectiveness.

Types of Filter Cloth and Material Specifications

Selecting the correct filter cloth involves evaluating the material, weave pattern, and micron rating based on your application’s requirements. Here’s a detailed look at the most commonly used filter cloth materials and their properties.

| Material | Temperature Resistance | Chemical Resistance | Common Applications | Advantages |

|---|---|---|---|---|

| Polypropylene (PP) | Up to 90°C (194°F) | Excellent resistance to acids and alkalis | Wastewater, chemicals, food processing | Lightweight, economical, easy to clean |

| Polyester (PET) | Up to 150°C (302°F) | Moderate resistance | Pharmaceuticals, textiles, mining | High tensile strength, stable performance |

| Nylon (PA) | Up to 120°C (248°F) | Moderate chemical resistance | Food filtration, beverage, pharmaceuticals | Smooth surface, durable, excellent flow rates |

| Cotton | Up to 105°C (221°F) | Limited chemical resistance | Sugar refining, breweries, edible oils | Natural fiber, cost-effective, good particle retention |

| PTFE (Teflon) | Up to 250°C (482°F) | Exceptional resistance | High-temperature chemical processing | Superior performance, high chemical tolerance |

Weave Patterns

-

Plain Weave – Provides fine particle retention and high clarity.

-

Twill Weave – Offers enhanced strength and faster flow rates.

-

Satin Weave – Ideal for sticky materials due to its smooth surface.

-

Mono-Multi Filament Mix – Combines durability with optimal particle separation.

Selecting Micron Ratings

The pore size, measured in microns, determines the smallest particles a filter cloth can capture:

-

Coarse Filtration: 50–200 microns (e.g., mineral processing).

-

Medium Filtration: 10–50 microns (e.g., food and beverage).

-

Fine Filtration: 1–10 microns (e.g., pharmaceuticals and chemicals).

Choosing the right material and specifications ensures that your filtration process operates at peak efficiency, minimizing blockages and maximizing throughput.

How to Choose the Right Filter Cloth for Your Application

Selecting an effective filter cloth involves evaluating operational conditions, particle characteristics, and chemical compatibility. Here’s a structured approach to guide your selection process:

Understand the Nature of Your Filtration Process

-

Determine whether you require pressure filtration, vacuum filtration, or gravity filtration.

-

Identify whether your priority is clarity of filtrate or maximum throughput.

Analyze the Properties of the Slurry

-

Particle Size & Shape – Larger, angular particles require different fabrics compared to fine, sticky particles.

-

Filtrate Requirements – Industries like pharmaceuticals demand ultra-clear outputs, requiring fine-weave cloths.

-

Chemical Composition – Acidic, alkaline, or solvent-heavy slurries demand chemically resistant materials.

Match Material with Process Conditions

-

High temperatures? Consider PTFE or polyester.

-

Highly corrosive chemicals? Opt for polypropylene or PTFE.

-

Sticky residues? Use satin-weave cloth for easier cleaning.

Optimize Filtration Performance

-

Choose the correct weave and micron rating for desired efficiency.

-

Ensure proper cloth fitting to avoid leakage and bypassing.

-

Consider anti-blinding treatments or coatings for challenging slurries.

Maintenance and Lifespan Considerations

-

Invest in cloths with easy-clean properties for high-cycle operations.

-

Evaluate total cost of ownership instead of initial purchase price.

-

Work with suppliers who provide testing support and customization.

By following this structured selection process, you can significantly enhance your filtration outcomes, reduce energy consumption, and extend equipment life.

FAQs and Final Insights

FAQ 1: What is the lifespan of a filter cloth?

The lifespan of a filter cloth depends on factors such as material type, operational pressure, chemical exposure, and cleaning frequency. For example, polypropylene filter cloths used in wastewater treatment may last between 6 to 18 months, while PTFE filter cloths in high-temperature chemical processing can last up to 3 years. Regular inspection and proper cleaning routines are essential to maximize longevity.

FAQ 2: How do I clean and maintain filter cloth effectively?

Effective cleaning depends on the material and the type of contaminants. Options include:

-

Backwashing with clean water to dislodge particles.

-

Chemical soaking to dissolve stubborn residues.

-

Ultrasonic cleaning for precision applications.

Always consult your supplier for recommended cleaning protocols to avoid damaging the fabric or altering its pore size.

Choosing the right filter cloth is critical for ensuring reliable, efficient, and cost-effective filtration. By understanding the material properties, weave patterns, and performance characteristics, industries can achieve better product quality, meet regulatory standards, and minimize operational costs. At SMCC, we specialize in providing high-performance filter cloth solutions tailored to diverse industrial needs. Our expert team works closely with clients to deliver customized filtration solutions that optimize productivity and reduce downtime.

If you are looking for premium-quality filter cloth or need assistance selecting the right one for your application, contact us today to discuss your requirements and discover how SMCC can support your business.