How Does Cotton Filter Cloth Improve Industrial Filtration Efficiency?

In industrial filtration systems, Cotton Filter Cloth plays a vital role in separating impurities, liquids, and fine particles across a variety of applications — from wastewater treatment to pharmaceutical manufacturing. Unlike synthetic materials, cotton-based filter media are natural, biodegradable, and possess a unique balance of absorbency and durability.

Cotton fibers are naturally twisted and interlocked, forming a fine porous structure that traps contaminants efficiently without sacrificing fluid flow. This natural design provides an excellent balance between filtration precision and permeability, allowing operators to maintain consistent flow rates and reduce downtime.

The high-temperature resistance of cotton fibers also makes the material suitable for environments where heat stability is essential. In addition, its anti-static and chemical-resistant characteristics ensure safety and reliability during long operational cycles.

Cotton filter cloths are widely used in industries such as:

-

Food and beverage: for juice clarification, sugar filtration, and dairy separation.

-

Mining and metallurgy: for separating minerals, sludge, and metal particles.

-

Chemical processing: for acid-base filtration and catalyst recovery.

-

Pharmaceutical: for high-purity and sterile filtering applications.

How Does Cotton Filter Cloth Work in Filtration Systems?

Cotton filter cloth operates on the principle of mechanical and surface filtration. When liquid or air passes through the fabric, contaminants are physically trapped by the interwoven cotton fibers. Over time, a layer of captured particles — known as the filter cake — builds up on the cloth, enhancing filtration efficiency by creating a secondary filtering barrier.

Let’s break down how it functions in different industrial systems:

-

In Pressure Filtration: The cloth is installed on filter presses where pressure forces the fluid through the fabric. The solid particles remain on the surface, forming a cake that is periodically removed.

-

In Vacuum Filtration: The negative pressure pulls liquid through the cotton cloth while solids accumulate on the top layer.

-

In Air Filtration: Cotton filter cloth acts as a dust collector, removing airborne particles from exhaust or intake systems.

Technical Specifications Overview

| Parameter | Specification | Description |

|---|---|---|

| Material Composition | 100% Cotton Fiber | Natural, biodegradable, and chemical-resistant |

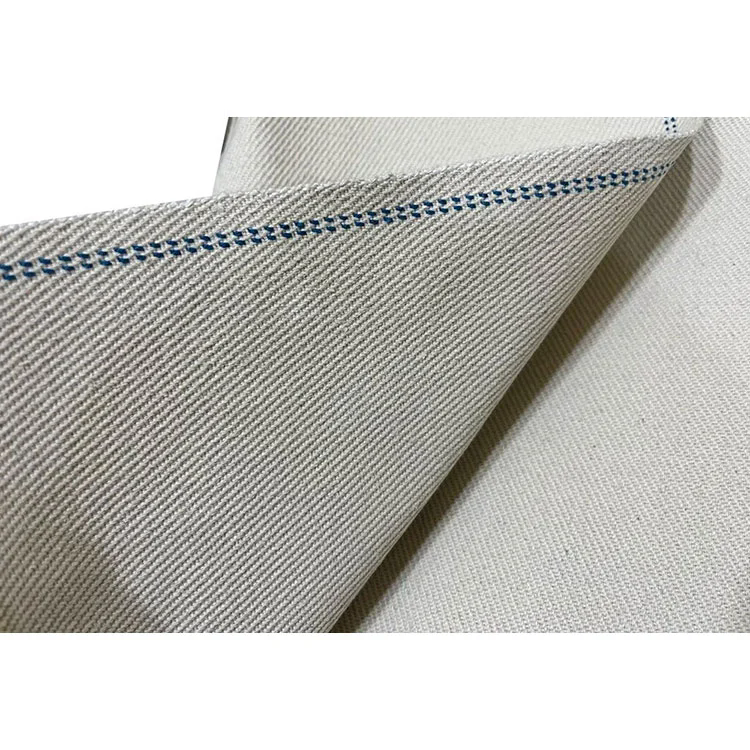

| Weave Type | Plain / Twill / Satin | Determines flow rate and particle retention |

| Filtration Precision | 5 – 100 Microns | Adjustable according to industrial need |

| Temperature Resistance | Up to 150°C | Ideal for high-heat applications |

| Weight Range | 150 – 500 g/m² | Customizable for durability and flexibility |

| pH Range | 4 – 9 | Stable in mild acid and alkaline environments |

| Tensile Strength | 400 – 800 N | Ensures mechanical endurance under pressure |

| Surface Treatment | Singed / Calendered / Mercerized | Enhances smoothness and clog resistance |

The selection of the right weave type and surface finish determines the filter cloth’s performance, lifetime, and cleaning frequency. For instance, a twill weave enhances mechanical strength and durability, while calendered surfaces minimize clogging and simplify cake release.

Why Industries Choose Cotton Filter Cloth Over Synthetic Options

One of the most common questions in industrial filtration is: Why use cotton instead of polyester or polypropylene? The answer lies in the unique performance characteristics of cotton that align with environmental goals, cost efficiency, and operational performance.

a. Environmental Benefits

Cotton is a renewable, eco-friendly material. As industries shift toward sustainable manufacturing, cotton filter cloth offers a natural alternative that decomposes without releasing microplastics into water systems.

b. Superior Particle Retention

Cotton fibers swell slightly when exposed to moisture, which helps close the fabric’s micro-pores — improving filtration precision and preventing fine particles from escaping.

c. Chemical and Heat Resistance

Cotton filter cloth withstands exposure to moderate acids and alkaline solutions and retains integrity up to 150°C, making it ideal for high-temperature processing in chemical, food, and pharmaceutical plants.

d. Easy Maintenance and Reusability

Due to its natural flexibility and structure, cotton filter cloth can be cleaned, washed, and reused multiple times without losing its filtration quality. This durability reduces the need for frequent replacements and lowers operational costs.

e. Cost-Effectiveness

Compared to synthetic fibers, cotton filter cloth is more cost-efficient in long-term applications. Its reusability, easy handling, and adaptability to diverse filtration systems lead to significant savings in both maintenance and energy costs.

How to Select and Maintain the Right Cotton Filter Cloth for Your Industry

Choosing the right cotton filter cloth involves more than selecting a fabric type; it requires a detailed understanding of the working environment, fluid properties, and filtration requirements. Here are the key factors to consider:

a. Identify Filtration Medium and Particle Size

Determine whether the filtration involves liquid or air, and the size and nature of particles being filtered. For fine filtration (5–20 microns), a tightly woven plain weave is ideal; for larger particles, a twill weave offers higher flow rates.

b. Match Temperature and Chemical Conditions

Check the operating temperature and chemical exposure level. Cotton filter cloth performs optimally between room temperature and 150°C, and within a pH range of 4–9.

c. Select Appropriate Weight and Thickness

Heavier cloths (350–500 g/m²) are used in pressure filtration for longer service life, while lighter cloths (150–300 g/m²) work well in vacuum and gravity systems.

d. Consider Surface Finish Options

Surface treatments like calendering, singeing, or mercerization improve performance. Calendering tightens the weave, singeing removes loose fibers for cleaner filtration, and mercerization enhances strength and chemical stability.

e. Maintenance Guidelines

Regular maintenance extends the lifespan of cotton filter cloth.

-

Backwash after every filtration cycle to remove surface cake.

-

Avoid harsh detergents that can weaken fibers.

-

Air dry rather than using high heat, which can shrink the cloth.

-

Inspect edges and seams regularly for wear and replace as needed.

Common FAQs About Cotton Filter Cloth

Q1: How long does a cotton filter cloth last in industrial use?

A high-quality cotton filter cloth can last from 6 months to 2 years, depending on operating pressure, temperature, cleaning frequency, and chemical exposure. Regular maintenance significantly extends its service life.

Q2: Can cotton filter cloth be customized for specific applications?

Yes. Cotton filter cloth can be customized in weave type, weight, pore size, and surface treatment according to your process requirements. Manufacturers like SMCC provide tailored solutions that match the viscosity, temperature, and particle load of your filtration system.

The Future of Cotton Filter Cloth: A Sustainable Path Forward

As industries transition to sustainable and energy-efficient processes, cotton filter cloth is regaining importance as a reliable, eco-conscious solution. Its biodegradable composition, renewable source, and robust mechanical properties make it a perfect replacement for petroleum-based synthetics.

Recent innovations in cotton treatment technology — such as enzyme pre-treatments and surface nanocoating — further enhance its filtration precision, mechanical strength, and resistance to fouling. These advancements allow cotton filter cloth to meet the increasingly strict environmental and quality regulations across global industries.

At SMCC, we specialize in developing high-performance cotton filter cloths designed to meet diverse industrial needs — from food processing and chemical filtration to pharmaceutical production and mining. Each product is engineered with precision to ensure long-term efficiency, stability, and sustainability.

If you are looking to improve your filtration system performance, contact us today to learn how SMCC’s advanced cotton filter cloth solutions can help optimize your production process while reducing costs and environmental impact.