How to Choose an Air Filter That Actually Solves Your Air Problems?

2025-12-22

Quick promise:

If you’ve ever bought an Air Filter that “looked right” but didn’t fix dust, odors, allergies, or rising energy bills, this article is for you. We’ll cover sizing, efficiency ratings, airflow trade-offs, replacement timing, and a simple decision process you can reuse every time.

Note: This is general guidance for filtration selection and maintenance; for medical concerns or severe indoor air issues, consult qualified professionals.

Abstract

Choosing the right Air Filter sounds simple—until you’re staring at different sizes, “nominal vs actual” measurements, confusing efficiency labels, and marketing claims that ignore the one thing your HVAC system cares about: airflow. A filter that’s too restrictive can increase pressure drop, reduce comfort, and push fans to work harder. A filter that’s too weak can leave you with dusty surfaces, irritated sinuses, and equipment that clogs faster than it should.

This guide breaks down what matters (and what doesn’t), gives you a clean checklist for matching a filter to your goal, and shows how to avoid the most expensive mistake: buying “high efficiency” without checking whether your system can handle it. You’ll also learn how OEM customization and consistent quality control—like the approach used by Qingdao Star Machine Technology Co.,Ltd.—can help procurement teams standardize filters across sites.

Table of Contents

- Outline

- The real pain points buyers face

- Air Filter basics in plain English

- Sizing and fit: the fastest way to win or lose

- Efficiency ratings and what they actually mean

- Airflow vs filtration: how to balance the trade-off

- Filter types compared (with a buyer’s table)

- Replacement timing: stop guessing, start managing

- Procurement tips for multi-site buyers and OEM programs

- FAQ

- Wrap-up and next steps

Outline

- Identify your main goal: dust control, allergy relief, odor reduction, or equipment protection

- Confirm exact size and depth (and why “nominal” can mislead)

- Choose an efficiency level that your system can support

- Pick a media type that matches your environment (home, office, light industrial, high particulate areas)

- Set a replacement schedule based on load, not wishful thinking

- Standardize for procurement: specs, QA, packaging, and OEM options

The real pain points buyers face

Most people don’t fail at buying an Air Filter because they don’t care. They fail because the market is noisy, and the “best filter” depends on your system and your air. Here are the most common problems I see buyers trying to solve:

- Dust that returns fast even after cleaning (often under-filtration or bypass air leaks).

- Allergy symptoms indoors (pollen, pet dander, fine particles; sometimes you need a better media or tighter sealing).

- Odors that linger (a particle filter alone may not address gases; carbon layers can help in some cases).

- Higher energy bills after switching to a “higher efficiency” filter (pressure drop can rise if the system isn’t designed for it).

- Uneven comfort or weak airflow at vents (restricted airflow, dirty coils, or the wrong filter thickness).

- Short filter life (high particulate load, poor pre-filtration, or incorrect placement/fit).

- Procurement inconsistency across buildings (different sizes, vendors, or specs lead to stockouts and quality variation).

The good news: once you use a repeatable selection process, the decision becomes boring—in the best way.

Air Filter basics in plain English

An Air Filter is a media barrier designed to capture airborne particles as air moves through your HVAC or ventilation system. That “capture” happens through a mix of mechanisms (like interception, impaction, and diffusion), but you don’t need a physics degree to buy correctly.

What you do need is clarity on three variables:

- Fit: If air can slip around the filter, performance drops no matter how “high grade” the media is.

- Efficiency: How well the filter captures particles of different sizes (not all dust is equal).

- Resistance: How much the filter restricts airflow (pressure drop), which impacts comfort and energy use.

Think of it like choosing shoes: the “best” pair is the one that fits your foot and the job you’re doing, not the one with the fanciest label.

Sizing and fit: the fastest way to win or lose

If you only remember one thing, remember this: an Air Filter that doesn’t fit is an air bypass machine. When gaps exist, air takes the path of least resistance—around the filter, not through it.

Nominal vs actual size

Many filters are sold using “nominal” dimensions (a rounded label size), but the “actual” physical size can be slightly smaller to fit the frame properly. That’s normal. The problem happens when buyers assume the label is exact and order without measuring the housing or referencing the equipment spec.

Thickness matters more than people expect

A 1-inch filter and a 4-inch filter are not interchangeable choices, even if the face size is the same. Thicker filters often provide:

- More media area (often longer service life)

- Lower resistance at the same efficiency (often easier on airflow)

- More stable performance as dust loads up

If your system supports deeper filters, it’s often a quiet upgrade—less maintenance drama, fewer emergency swaps, and better consistency.

Practical tip:

Measure the filter slot (or confirm the equipment spec), then choose a filter with the correct face size and depth. If you’re managing multiple sites, standardize sizes where possible to simplify inventory.

Efficiency ratings and what they actually mean

Different regions and industries use different standards, but the buying principle stays the same: your Air Filter should be efficient enough to meet your goal without choking your system.

What should you aim for?

- Basic protection: Good for equipment protection and visible dust reduction, but not ideal for fine particles.

- Balanced performance: A common sweet spot for many homes and offices—captures more fine particles while keeping airflow reasonable.

- High efficiency / HEPA-level: Powerful for very fine particles, but may require system compatibility, proper sealing, and sometimes higher fan capacity.

The mistake is treating “higher efficiency” as universally better. If airflow drops too much, you can end up with poor comfort, noisy operation, frozen coils, or higher energy use. For many real-world systems, a well-fitted, medium-to-high efficiency filter is the smartest total-cost choice.

Airflow vs filtration: how to balance the trade-off

Every Air Filter is a compromise between capturing more particles and allowing air to pass freely. Your job is not to eliminate the trade-off—it’s to choose the best point on the curve for your building.

Use this decision shortcut

- If allergies are the priority: Upgrade efficiency, but verify airflow and use good sealing to avoid bypass.

- If energy and airflow are the priority: Consider a deeper filter (more media area) rather than only increasing density.

- If dust load is high: Improve replacement frequency and consider staged filtration (a pre-filter before a finer filter).

- If odors are the priority: Evaluate activated carbon or specialized media, not just particle capture.

A buyer’s rule of thumb:

Don’t buy “the highest rating.” Buy the highest rating your system can handle comfortably for your operating hours and environment.

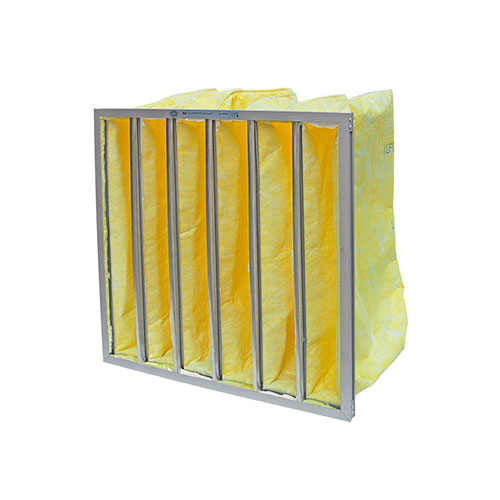

Filter types compared (with a buyer’s table)

The media structure and build quality are where an Air Filter becomes either dependable or disappointing. Here’s a practical comparison to help you choose without getting lost in jargon:

| Filter Type | Best For | Strengths | Watch Outs |

|---|---|---|---|

| Basic panel / coarse filters | Equipment protection, low-load environments | Low cost, low resistance when clean | Limited fine-particle capture; may not help allergies much |

| Pleated filters | Most homes, offices, general HVAC | Better surface area; good balance of capture and airflow | Cheap pleats can collapse; fit/seal quality varies |

| Electrostatic / enhanced media | Finer particle capture without extreme restriction | Improved capture of smaller particles (depends on design) | Performance varies by manufacturer; confirm real specs |

| HEPA-style / high-efficiency filters | High sensitivity spaces, specialized applications | Strong fine-particle filtration | Can increase resistance; system compatibility and sealing are critical |

| Carbon or odor-control layers | Odors, VOC concerns (limited scope) | Helps with certain smells and gaseous contaminants | Capacity is finite; not a replacement for ventilation/source control |

For procurement teams, consistency is the hidden KPI. A reliable supplier should offer stable materials, controlled dimensions, and repeatable performance. That’s why many buyers prefer working with manufacturers like Qingdao Star Machine Technology Co.,Ltd. for OEM programs—so they can lock in specs, packaging, labeling, and batch consistency for long-term supply.

Replacement timing: stop guessing, start managing

The “change it every X months” advice is a starting point, not a law of nature. Your Air Filter replacement interval depends on: occupancy, pets, outdoor pollution, renovation work, operating hours, and whether you run continuous fan mode.

A practical schedule framework

- High load (pets, smoke, heavy dust, construction): check monthly; replace as needed

- Typical residential or office use: check every 6–8 weeks; replace when visibly loaded

- Deeper filters (if system supports): often longer intervals, but still inspect regularly

Don’t ignore these warning signs

- Airflow feels weaker than usual

- Rooms take longer to heat/cool

- More dust on surfaces shortly after cleaning (possible bypass or saturation)

- HVAC seems louder or runs longer cycles

Pro tip for facilities: track replacement dates and conditions (clean / moderate / heavy) for 2–3 cycles. You’ll quickly see the “true” interval for each site.

Procurement tips for multi-site buyers and OEM programs

If you’re sourcing Air Filter products for multiple buildings, the goal is predictable performance and fewer surprises. Here’s what to standardize in your spec sheet:

- Dimensions: face size + depth + acceptable tolerance range

- Media and frame materials: suited to humidity, temperature, and particulate load

- Target efficiency: define the performance level you need (avoid vague “high efficiency” wording)

- Resistance expectations: request pressure drop guidance at typical airflow where applicable

- Quality checkpoints: pleat integrity, sealing, packaging protection, labeling accuracy

- OEM needs: custom branding, barcodes, carton marks, and consistent batch delivery

Why OEM matters:

With an OEM partner such as Qingdao Star Machine Technology Co.,Ltd., you can align filter sizes and specifications across your portfolio, reduce emergency substitutions, and keep maintenance teams from “making it fit” with the wrong product.

FAQ

Is a higher-efficiency Air Filter always better?

Not always. A higher-efficiency Air Filter can capture more fine particles, but it may also increase airflow resistance. The best choice is the highest efficiency your HVAC system can handle without sacrificing comfort, runtime, or energy cost.

Why does my filter size label not match my measurement?

Many filters use a “nominal” label size, while the actual product can be slightly smaller for proper installation. Always verify the system requirement or measure the filter slot to avoid looseness (bypass) or forced fit.

How often should I replace an Air Filter?

It depends on your environment and usage. A common approach is to inspect every 4–8 weeks and replace when loaded. Homes with pets, smoke exposure, or high outdoor pollution often need more frequent changes.

My home still feels dusty—does that mean the Air Filter is bad?

Not necessarily. Dust can come from bypass gaps, leaky ductwork, dirty coils, poor housekeeping during renovations, or outdoor infiltration. Start by confirming fit and sealing, then consider upgrading efficiency or switching to a deeper filter if your system supports it.

Do I need HEPA filters for everyday HVAC?

HEPA-level filtration can be excellent for sensitive environments, but not every HVAC system is designed for it. If you need very high fine-particle control, consider system compatibility, sealing, and potentially staged filtration solutions.

Can I order custom sizes or private label Air Filters?

Yes. Many manufacturers offer OEM customization for Air Filter sizes, packaging, and labeling. This can be especially helpful for procurement teams standardizing inventory and performance across multiple sites.

Wrap-up and next steps

Buying the right Air Filter isn’t about chasing a buzzword—it’s about matching fit, efficiency, and airflow to your real-world conditions. When you get those three right, you’ll typically see cleaner indoor air, steadier HVAC performance, and fewer “why is the system acting weird” moments.

If you’re sourcing for a building portfolio or need consistent OEM specifications, partnering with an experienced manufacturer like Qingdao Star Machine Technology Co.,Ltd. can simplify your supply chain while keeping performance predictable.

Ready to stop guessing?

Share your required size, depth, target efficiency, and usage scenario, and we can recommend a practical Air Filter configuration that balances cleanliness, airflow, and cost. For quotes, OEM options, or technical matching support, contact us and tell us what problem you’re trying to solve.