PET Spiral Filter-press Mesh

Send Inquiry

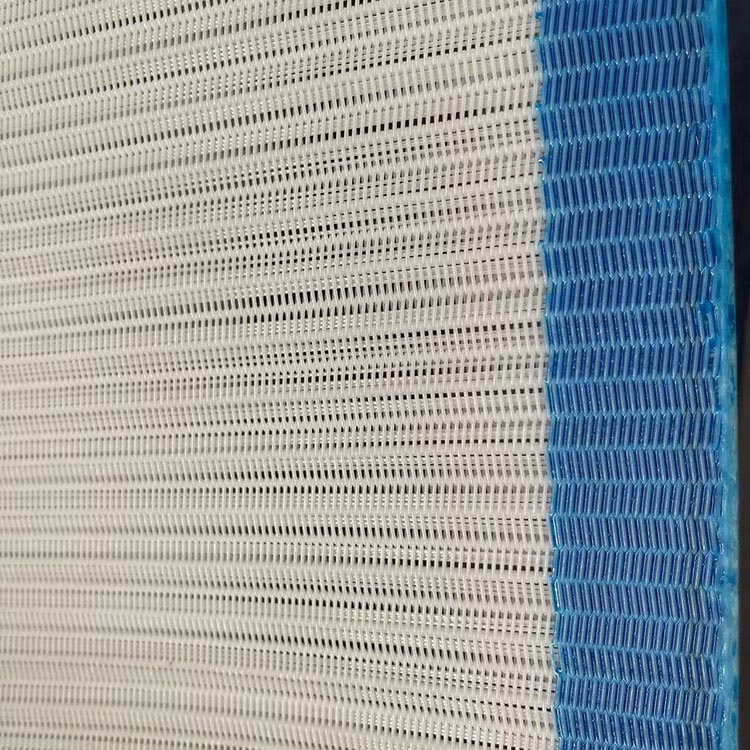

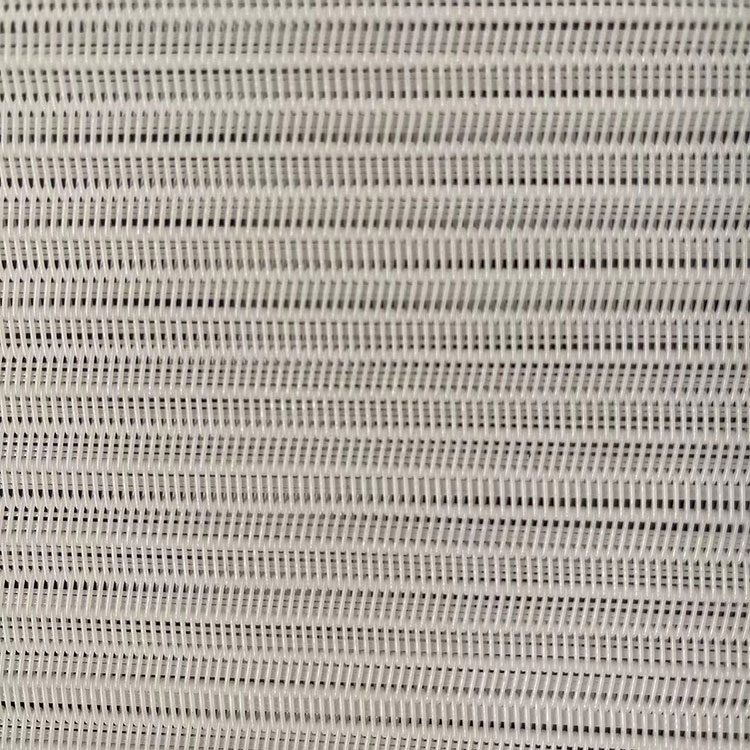

PET spiral filter-press Mesh is to winding polyester monofilaments into helical ring and connect with weft threads to form helical mesh. The mesh has a smooth surface, excellent air permeability and high temperature resistance. It also has an interface that makes installation easier.

The addition of these filler filaments enables the PET spiral filter mesh to have better filter press performance. The presence of padded silk increases the thickness and robustness of the mesh belt, thus increasing the abrasion resistance and durability of the mesh belt during stamping.

PET spiral filter-press Mesh is mainly used in belt dewatering machines. In belt dewaterers, polyester press filters are used as part of filtration and dehydration devices. They are responsible for separating solid particles suspended in water and removing the water from the solid matter through a crushing process.

The PET spiral filter-press Mesh is widely utilized in wastewater treatment, sludge treatment, chemical industry, food processing and other industries. These systems are adept at handling large quantities of suspended solids, ensuring efficient dewatering and filtration to meet the demand for uncontaminated, dry products in industrial production.

The significance PET spiral filter-press Meshs in belt dewatering equipment and various industrial tools lies that it enhances filtration and dehydration functions and contributes to efficient solid-liquid separation and material handling.

Product Parameter

| Types of Spiral Dryer Fabric | Wire Diameter(mm) | Strength(N/cm) |

Air Permeability (m3/m2h) |

||

| Warp | Weft | Filler | Area of the surface | ||

|

Large Loop |

0.90 | 1.10 | 0.90×4 | ≥2300 | 10231±500 |

| 0.90 | 1.10 | 0.90×5 | ≥2300 | 6317±500 | |

|

Medium Loop |

0.70 | 0.90 | 0.80×3 | ≥2000 | 10320±500 |

| 0.70 | 0.90 | 0.80×4 | ≥2000 | 8500±500 | |

| Small Loop | 0.52 | 0.70 | 0.68×3 | ≥1800 | 2850±500 |

| Medium Loop (Flat Wire) | 0.70 | 0.70 | (J)0.24*0.85 | ≥2000 | 10100±500 |