Centrifugal Filter Bag

Centrifugal Filter Bag: High-Efficiency Filtration for Industrial Applications Centrifugal filter bags are engineered for demanding industrial filtration processes that require high flow rates, superior particle retention, and reliable performance. These bags are specifically designed to work with centrifugal pump systems, leveraging rotational force to drive fluids through the filter media, thereby capturing contaminants efficiently. They are widely used in industries such as chemicals, pharmaceuticals, food and beverage, water treatment, and metalworking. Key Advantages of Using Centrifugal Filter Bags: - Enhanced filtration efficiency due to centrifugal force aiding fluid passage. - High dirt-holding capacity, reducing the frequency of bag changes. - Compatibility with a wide range of liquids, including corrosive and high-viscosity fluids. - Easy installation and replacement, minimizing downtime in industrial operations. - Available in multiple micron ratings and materials to suit specific application needs. Product Specifications: Our centrifugal filter bags are manufactured to meet strict quality standards, ensuring consistent performance and durability. Below is a detailed overview of the product parameters. Material Options: - Polypropylene: Ideal for general-purpose applications, resistant to most chemicals, and cost-effective. - Nylon: Offers excellent abrasion resistance and durability for heavy-duty use. - Polyester: Suitable for high-temperature environments and provides good chemical resistance. - PTFE (Teflon): Best for highly aggressive chemicals and extreme temperature conditions. - Stainless Steel Mesh: Used for reusable applications requiring robust mechanical strength. Micron Ratings Available: - 1 micron: For ultra-fine filtration, capturing microscopic particles. - 5 microns: Effective for removing fine sediments and contaminants. - 10 microns: Common in general industrial and chemical processing. - 25 microns: Suitable for pre-filtration or larger particle separation. - 50 microns: Used in applications where larger debris needs removal. - 100 microns: Ideal for coarse filtration and protecting downstream equipment. Standard Sizes and Dimensions: Our centrifugal filter bags come in various sizes to fit different housing systems. The following table provides standard dimensions.

| Bag Size (Length x Diameter) | Compatible Housing Models | Maximum Flow Rate (GPM) | Recommended Operating Pressure (PSI) |

|---|---|---|---|

| 7" x 18" | Model CF-100, CF-200 | 100 | 150 |

| 8" x 20" | Model CF-300, CF-400 | 150 | 150 |

| 9" x 25" | Model CF-500, CF-600 | 200 | 125 |

| 10" x 30" | Model CF-700, CF-800 | 250 | 100 |

Hot Products

Nomex Filter Bag

Nomex filter bags (aramid filter bags) can resist high temperatures and keep their shape and stability even when they are as hot as 250°C. This type of filter bag can be used in places like thermal power generation, powder metallurgy or other heavy industries. It is perfect for the most extreme industrial environments.Catalytic Filter Bag

The large amount of harmful substances (chemicals such as dioxins and furans) produced in waste incineration are hazardous to human beings and cause great pollution to the environment, which requires us to do better in the dust removal and filtration industry. In response to the harmful substances produced during the incineration of domestic waste, we have upgraded and modernised the technology of dust removal and filtration, and introduced new catalytic filter bags in order to face the majority of customers with high requirements, and to build a sustainable future for mankind.Submerged Solenoid Valve

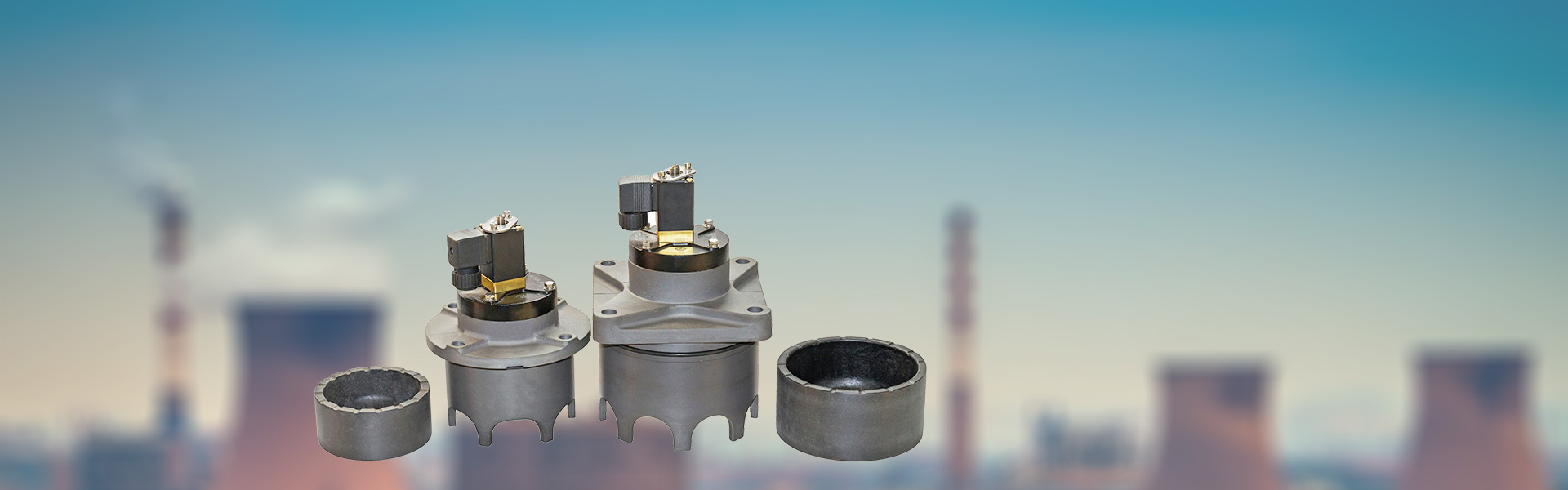

Qingdao Star Machine's Submerged Solenoid Valve is a type of piston pulse valve, can be used in baghouse systems. The submerged design will reduce the possibility of air leakage. Use the submerged pulse valve to clean air will save energy and cost.Optipow105 Pulse Jet Valve

Qingdao Star Machine, as the core manufacturer of Optipow105 Pulse Jet Valve, The valve maintains technological leadership in the field of flue gas treatment. The pulse valve we developed has enabled PM2.5 filtration efficiency to exceed 99.97% while simultaneously reducing carbon emissions by 1.2kg per ton of product and promoting the evolution of industrial dust removal systems towards the goal of carbon neutrality. This valve type can achieve 0.3-second pulse cycle control accuracy (deviation <±2%) and is suitable for 0.6- 0.8MPa dynamic pressure conditions.Pulse Valve for Baghouse Dust Collector

Qingdao Star Machine is a professional manufacturer Pulse Valve for Baghouse Dust Collector,It is an important part of the bag dust collector, mainly used for blowing to remove the dust on the bag. Its working principle is to use compressed air to blow instantaneously, form a pulse, reverse blowing ash.Pilot Solenoid Valve

As the core driving component of the Starmachinechina pulse valve series, the SMCC economical pilot solenoid valve controls the precise opening and closing action of the Starmachinechina pulse jet valve diaphragm through electromagnetic effect. We have built a complete technical service system, and the professional engineer team can provide: 1) Accurate product parameter analysis 2) Working condition adaptation solution design 3) Full process technical Q&A. For various working condition problems during the use of the product, we promise to respond quickly and provide targeted solutions. If you need technical consultation or emergency support, please feel free to contact us.