Edible Oil Filter Cloth

Send Inquiry

Product Descripton

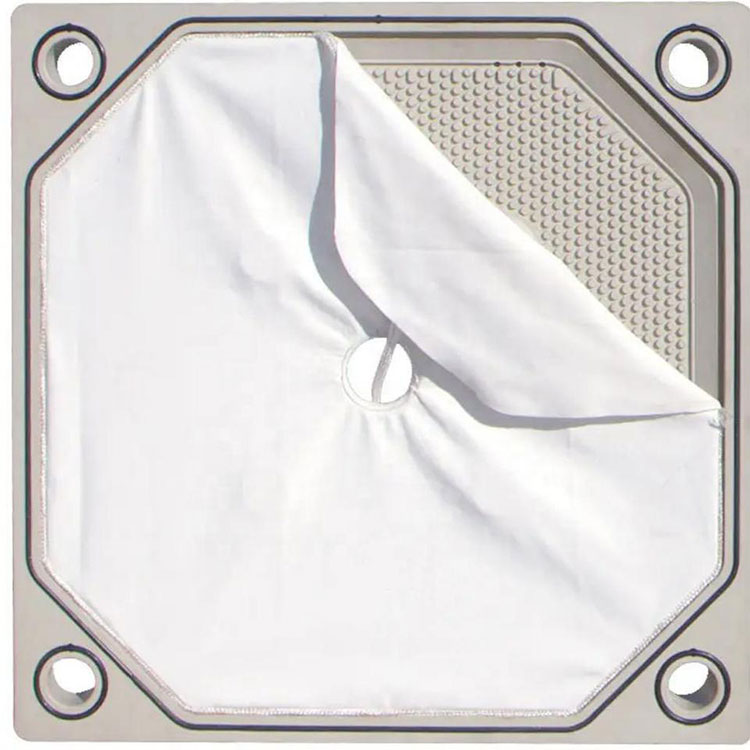

The edible oil filter cloth produced by Qingdao Star Machine is considered to be an efficient solid-liquid separator, especially suitable for the processing of vegetable oil. It separates oil from oilseeds at relatively low pressure, while preventing oil droplets from splashing. Suitable for pressing, degumming, decoloring, dewaxing and filtration of various products.

Edible oil filter cloth separates oil from water. The product is made of food safety related materials and fully complies with global standards food contact materials.

The filter cloth is customizable and suitable for all types of filter presses. It can be cleaned with a water cannon. The use of edible oil filter cloth can prevent chemical reactions of oil during the filtration process. This ensures not only the purity of the oil, but also the safety of food. Edible oil filter cloth can be applied to various mechanical equipment such as plate frame press filter machine, centrifuge and blade filters to meet the strict requirements of current industrial production.

Product Advantage

Filtration Accurancy

The filtration accuracy of edible oil filter cloth can reach 0.1 micron to100 micron, which can effectively capture the trace pollutants in oil, thus greatly improving the quality of oil.

High temp and Corrision Resistance

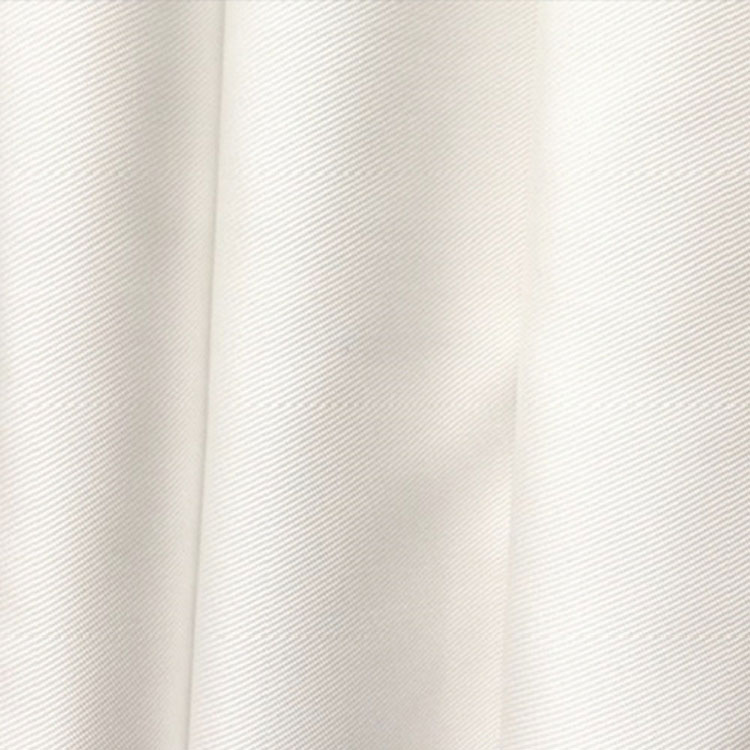

The edible oil filter cloth is made of strong polyester or polyamide (PA) fibers and can withstand temperature variations of -40°C to 150°C, especially for extreme environments such as high-temperature deodorization and steam cleaning. Edible oil filter cloth can be coated with acid and alkali resistant coatings. This unique treatment method can resist chemical degradation during acid washing, alkali refining and refining and help prolong the life of the filter cloth.

Can be Customized

Qingdao Star Machine offers various weaving methods filter cloth, such as plain weave, twill weave and satin weave, and combines surface treatment techniques such as calendering, singeing or PTFE coating to meet different needs, such as primary and advanced filtration in the pressing process. Our filter cloths can be customized in size to meet the special requirements of filtration systems in different countries and brands, ensuring the smooth configuration and efficient sealing of the system.

Environmental Friendly

The edible oil filter cloth can promote over 50 cycles of reuse, reduce waste generation, and always adhere to the principle of sustainable production. The advantages brought by the product enhance work efficiency, reduce expenses, and increase work efficiency. The filtration efficiency has increased by more than 30%, while the residual oil ratio remains below 0.3%, which significantly reduces the loss of raw materials and the cost of waste residue treatment. Its tensile strength exceeds 800N/5cm, its wear resistance meets ISO standards, and its service life is 2 to 3 times that of standard filter cloth.

Food Grade

The edible oil filter cloth contains no silicone oil or fluorescent components at all, thereby reducing the risk of secondary contamination of edible oil.