Dust Collector Filter Bag

In industrial settings, maintaining clean air is paramount for both operational efficiency and regulatory compliance. An essential component in achieving this is the use of high-performance Air Dust Removal Filter Bag. These filter bags are specifically engineered to capture fine particulate matter, ensuring that exhaust air meets stringent environmental standards. For applications requiring chemical resistance and durability, the Polypropylene Air Dust Removal Filter Bag offers an excellent solution. Both types are designed to handle demanding conditions, providing reliable dust control in various industrial processes.

The Dust Collector Filter Bag is engineered with precision to deliver superior filtration performance. Key parameters are detailed below to help you select the ideal filter bag for your specific application. These specifications ensure optimal efficiency, longevity, and compatibility with different dust collection systems.

- Material Composition: Available in Polyester, Polypropylene, Nomex, and P84, each selected for specific temperature and chemical resistance properties.

- Filtration Efficiency: High-efficiency rating, capable of capturing particles as small as 1 micron.

- Operating Temperature Range: Varies by material; typically from -40°F to 500°F (-40°C to 260°C).

- Bag Dimensions: Customizable lengths and diameters to fit various dust collector models.

- Surface Treatment: Options include singed, calendered, or PTFE coated for enhanced dust release and cake discharge.

- Seaming Method: Ultrasonically welded or sewn seams for durability and leak-proof performance.

| Parameter | Specification | Application Notes |

|---|---|---|

| Material Type | Polyester, Polypropylene, Nomex, P84 | Select based on temperature and chemical exposure. |

| Air-to-Cloth Ratio | 2:1 to 6:1 (CFM/ft²) | Lower ratios for higher dust load applications. |

| Maximum Pressure Drop | 6-8 inches H₂O | Indicates resistance to airflow; monitor for bag life. |

| Weight (GSM) | 300 - 750 g/m² | Higher weight often correlates with increased durability. |

| Bag Construction | Circular, flat, or pleated designs | Choose based on collector type and space constraints. |

| Chemical Resistance | Varies by material (e.g., Polypropylene resists acids) | Critical for chemical processing or corrosive environments. |

| Moisture Resistance | Hydrophobic treatments available | Prevents blinding in high-humidity conditions. |

Hot Products

Solenoid Valve Coil

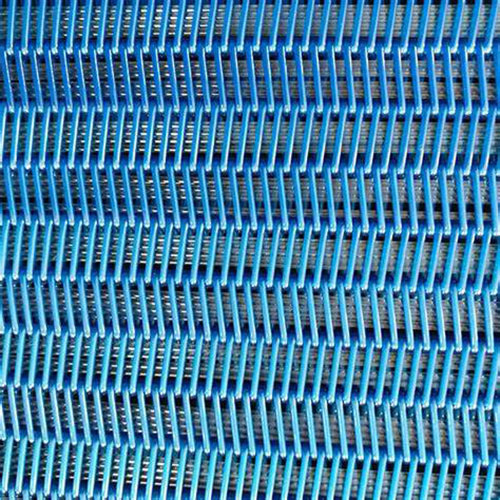

Qingdao Star Machine Technology Co.,Ltd. is a large-scale Dust removal equipment and purification equipment Solenoid Valve Coil manufacturer and supplier in China. We have three large research and production bases and one large marketing center for Dust removal valve, filter cloth, filter bag, and other related dust removal equipment and accessories We look forward to becoming your long-term partner in China.Sludge Dehydration Fabric

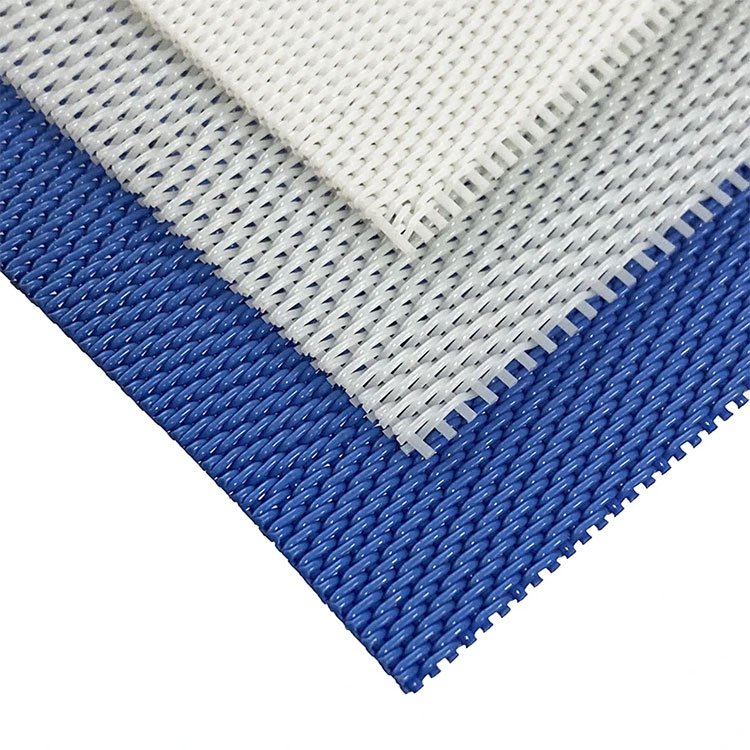

Qingdao Star Machine’s top quality Sludge Dehydration Fabric is also called Press- Filter Fabrics or Polyester Filter Belt ,which is mainly used for sludge dehydration, paper pulp and juice squeeze, mine smelting, mine tailings disposal and other pressure filtration industries.we can offer the sample to test the quality first for your assured procurement.Optipow135 Pulse Jet Valve

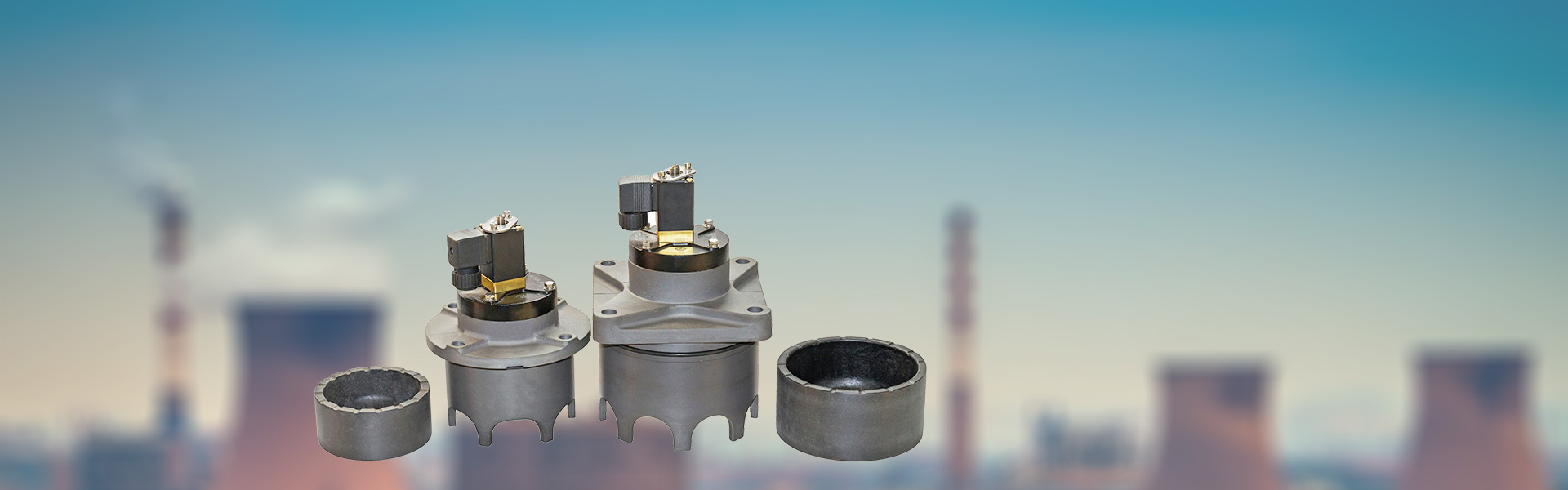

Optipow135 Pulse Jet Valve is from Qingdao Star Machine, It plays a switch role in the dust removal system of the pulse bag filter. It is controlled by receiving the output signal of the pulse jet control equipment, so that the dust is cleaned into the filter bag, so as to ensure the function and the dust removal effectiveness of the filter room.Optipow105 Pulse Jet Valve

Qingdao Star Machine, as the core manufacturer of Optipow105 Pulse Jet Valve, The valve maintains technological leadership in the field of flue gas treatment. The pulse valve we developed has enabled PM2.5 filtration efficiency to exceed 99.97% while simultaneously reducing carbon emissions by 1.2kg per ton of product and promoting the evolution of industrial dust removal systems towards the goal of carbon neutrality. This valve type can achieve 0.3-second pulse cycle control accuracy (deviation <±2%) and is suitable for 0.6- 0.8MPa dynamic pressure conditions.Piston Pulse Fabric Filter Cleaning Valve

Qingdao Star Machine Technology Co.,Ltd. is a large-scale Piston Pulse Fabric Filter Cleaning Valve manufacturer and supplier in China.We have over 20 years of experience in production and sales in the fields of dust removal and purification equipment, it is precisely based on our price and technological advantages,and our products can be OEM. Our Piston Pulse Fabric Filter Cleaning Valve cover most of the European, Asian and American markets. We look forward to becoming your long-term partner in ChinaDust Removal Pulse Solenoid Valve

Qingdao Star Machine, as a professional manufacturer Dust Removal Pulse Solenoid Valve, achieving a 98.6% customer repurchase rate in the field of industrial dust control. Our Dust Removal Pulse Solenoid Valve has great function, and can be used in severe environments.