Polypropylene Air Dust Removal Filter Bag

In industrial applications, maintaining air quality is critical for both operational efficiency and regulatory compliance. An effective solution for capturing airborne particulates is the Dust Collector Filter Bag. Specifically, the Polypropylene Air Dust Removal Filter Bag is engineered to provide superior performance in demanding environments. These filter bags are designed to handle a wide range of dust types and are a key component in systems such as baghouses and dust collectors. By utilizing these high-performance Air Dust Removal Filter Bag products, facilities can achieve higher filtration efficiency, reduced maintenance cycles, and prolonged equipment life. The robust construction ensures reliable dust collection, helping to protect both machinery and personnel from harmful particulate matter.

The Polypropylene Air Dust Removal Filter Bag is manufactured from high-quality polypropylene materials, offering excellent chemical resistance and durability. This makes it suitable for applications involving acidic or alkaline environments. The filter media is designed to provide a high dust-holding capacity while maintaining low pressure drop, which enhances overall system performance. Key features include its ability to be laundered and reused multiple times, providing cost savings over its lifecycle. The consistent performance of the Polypropylene Air Dust Removal Filter Bag ensures that industrial processes run smoothly, minimizing downtime and maintenance requirements.

Key Specifications of Polypropylene Air Dust Removal Filter Bag

- Material: 100% Polypropylene

- Maximum Continuous Operating Temperature: 190°F (88°C)

- Air Permeability: Customizable based on application needs

- Filtration Efficiency: Up to 99.9% on particles above 1 micron

- Standard Sizes: Custom lengths and diameters available

- Finish Options: Heat sealing, sewing, or ultrasonic welding

Performance Characteristics

| Property | Value | Test Method |

|---|---|---|

| Basis Weight | 5 - 10 oz/yd² | ASTM D3776 |

| Thickness | 0.5 - 1.5 mm | ASTM D5729 |

| Tensile Strength (Machine Direction) | 120 - 200 lbf/in | ASTM D5035 |

| Chemical Resistance | Excellent against most acids and alkalis | Industry Standard |

| Moisture Regain | Less than 0.5% | ASTM D2495 |

Typical Applications

- Cement and Asphalt Plants

- Pharmaceutical Manufacturing

- Food Processing Facilities

- Chemical Production Units

- Mining and Mineral Processing

Hot Products

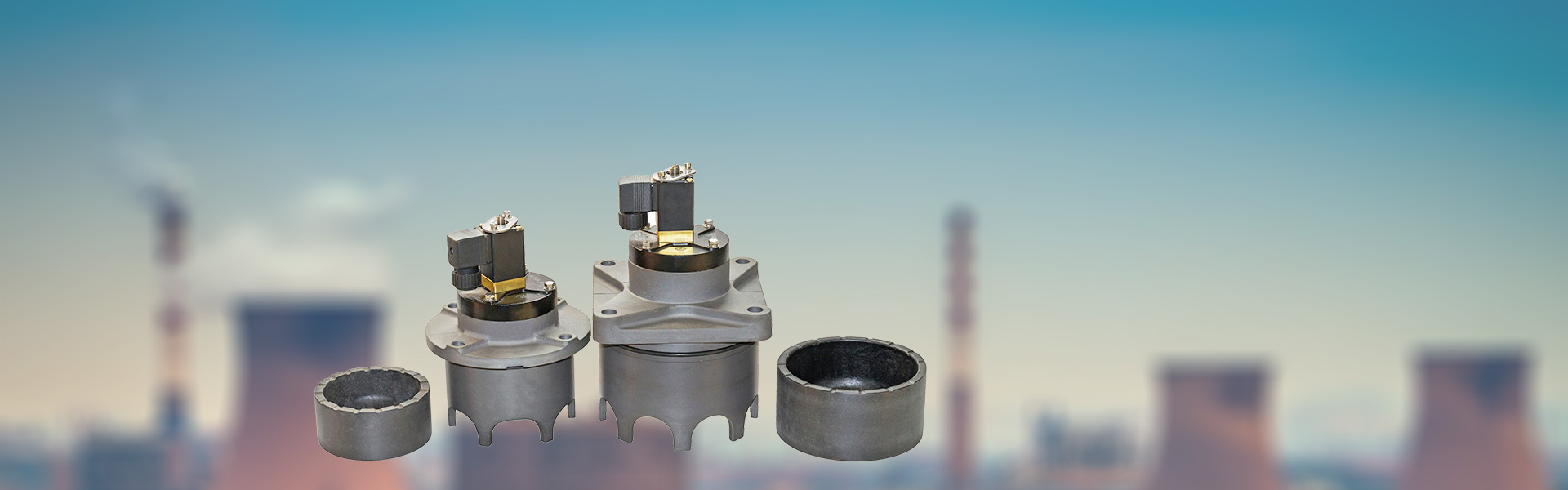

DB116 Nitrile Diaphragm Repair Kits for VNP216

As a professional filtration problem solving company, Qingdao Star Machine can provide many types of pulse valve diaphragm parts repair kits, such as DB116 Nitrile Diaphragm Repair Kits for VNP216. These repair kits can solve a wide range of problems that customers encounter when using different types of pulse valves, allowing them to maintain production for less money, saving them money.Wastewater Treatment Filter Cloth

Wholesale wastewater treatment filter cloth from Qingdao Star Machine, it is used to filter suspended matter and particulate matter in sewage material. It is an important part of sewage treatment equipment, which can realize the important process of sewage purification treatment.Sugar Industry Filter Bag

SMCC provides high quality sugar industry filter bags, our filter bag are made from good material,advanced production process,and with a 20 years filtration experience.Non-Woven Geotextile Fabric

Qingdao Star Machine can provide high quality NON-WOVEN GEOTEXTILE FABRIC. Geotextile it is a synthetic fibre as the main raw material, through the weaving process, knitting process, needle punching process and other different processes and become a kind of geosynthetics, at present in the project is mainly used for protection, isolation, anti-filtration, reinforcement, etc., in the water conservancy projects, road projects, tunnels and bridges and other fields of application is relatively wide. The most commonly used include short fibre needle punched non-woven geotextile , filament spunbond needle punched non-woven geotextile (also known as "filament geotextile") and filament woven geotextile several kinds.Dye Separation Filter Bag

Qingdao Star Machine's cheap Dye separation Filter Bag with high quality,that Materials usually include polyester fiber (PE), polypropylene fiber (PP), Nylon (Nylon) and polytetrafluoroethylene (PTFE). These materials have corrosion resistance, high temperature resistance, wear resistance and other characteristics, can effectively filter and separate dyes.Customized Liquid Filter Bag

At Qingdao Star Machine, we have customized liquid filter bags and standar filter bags. The customized liquid filter bags are made completely according to customer requirements to adapt to different customized usage environments.