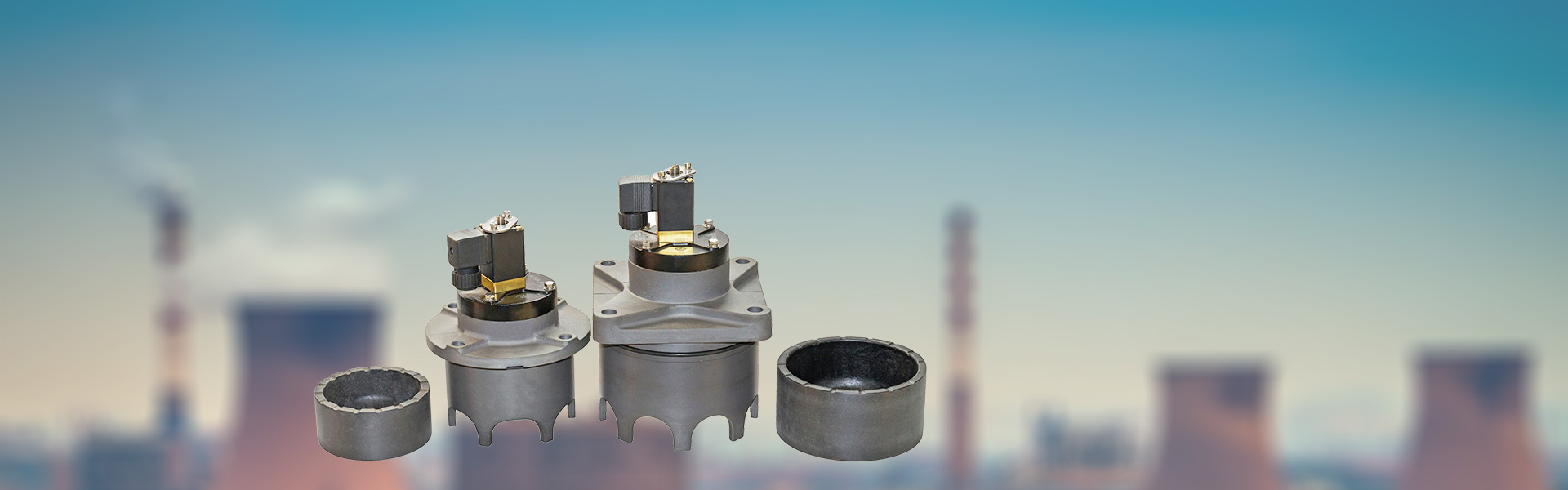

pulse membrane valve

Pulse Membrane Valve: Precision and Reliability for Industrial Applications

In demanding industrial filtration and dust collection systems, achieving optimal performance requires precise and reliable valve components. Our high-performance pulse valve is engineered to deliver powerful, instantaneous air pulses for effective media cleaning. For specialized systems requiring rapid, high-energy bursts, our advanced Pulse jet valve offers superior performance. When integration with legacy control systems is paramount, our compatible Alstom solenoid valve ensures seamless operation. Furthermore, for specific air cleaning applications demanding a robust and efficient solution, the optipow105 air cleaning valve provides exceptional durability and consistent airflow.

Detailed Technical Specifications of the Pulse Membrane Valve

The Pulse Membrane Valve is constructed with a focus on longevity and operational efficiency. The core of its design is a high-grade nitrile or Viton membrane, chosen for its exceptional resistance to wear, oil, and a wide range of temperatures. This ensures a consistent seal and a long service life, even in the most challenging environments. The valve body is typically machined from die-cast aluminum or engineered polymer, providing a perfect balance between lightweight properties and structural integrity. For demanding applications, stainless steel construction options are available to combat corrosive atmospheres. Advanced electromagnetic solenoids are integrated to guarantee fast response times and millions of reliable cycles, making the Pulse Membrane Valve a cornerstone of efficient baghouse and cartridge filter operations.

Key Performance Features:

- Rapid Response Time: Ensures instantaneous pulse delivery for maximum cleaning efficiency.

- Robust Membrane: High-quality elastomer for extended lifespan and reliable sealing.

- Corrosion-Resistant Body: Available in aluminum, polymer, and stainless steel to suit various environments.

- Low Power Consumption: Efficient solenoid design reduces operational energy costs.

- Easy Maintenance: Modular design allows for quick inspection and part replacement.

Technical Parameter Table

| Parameter | Specification | Unit |

|---|---|---|

| Operating Pressure | 0.3 - 0.8 | MPa |

| Voltage | 24 VDC / 110 VAC / 220 VAC | - |

| Orifice Diameter | 1 inch, 1.5 inch, 2 inch, 3 inch | inch |

| Ambient Temperature | -20 to +80 | °C |

| Media Temperature | Max. 120 | °C |

| Connection Type | NPT, BSPT, Flange | - |

| Duty Cycle | 100% (Intermittent) | - |

| IP Rating | IP65 | - |

Hot Products

Dust Removal Filter Bag Skeleton

The dust removal filter bag skeleton is the rib of the filter bag, which is lightweight, easy to install and maintain. The quality of the dust removal filter bag skeleton directly affects the filtration status and service life of the filter bag. Starmachinechina introduces dust removal bag framework manufacturing equipment and uses high-frequency welding machines to weld the framework in one go. The dust removal filter bag skeleton is made of iron wire or stainless steel wire with sufficient strength and rigidity. Treatment methods is such as galvanization, spray molding, and organic silicon plating. The dust removal filter bag skeleton processed by Starmachinechina using organic silicon technology can completely replace the stainless steel skeleton, greatly reducing the maintenance cost of the equipment. And each frame manufactured can meet the requirements of being lightweight, smooth, and straight. The annual production capacity is 2 million units, which can meet the urgent supply needs of customers.Dewatering Filter Bag

Dewatering bags (also called dewatering filter bags or sediment filter bags) are an effective, economical solution for filtering sediment, oil, and debris from pumped water.Normal Pressure Bulkhead Connector

NORMAL PRESSURE BULKHEAD CONNECTOR is used to connect the input end of the pulse valve to the tank. The normal pressure pipe is made of steel and can be welded to the tank. SMCC are committed to the bag dust collector accessories industry, provide various types of bulkhead connector and pulse jet valves of the pulse jet baghouse.Solid-Liquid Filter Bag

Qingdao Star Machine Technology Co.,Ltd. is a professional manufacturer and strong supplier of filter bags in China. The Solid-Liquid Filter Bag used in our production process have excellent chemical stability and heat resistance, making them the highest performing representative of the filter material industry and the most high-end variety among all commonly used filter materials. The liquid filter bag adopts advanced hot melt bonding technology to ensure the best bonding strength of the filter bag and prevent leakage.Screen Printing Nylon Filter Mesh

Qingdao Star Machine Screen Printing Nylon Filter Mesh is made from high-strength nylon and polyester material. This series of products has acid resistance, alkali resistance, hydrolysis resistance, and mold resistance. The Filtration of pickled food particles filter cloth can choose different specifications of raw material combinations and different organizational structures, forming various products with different filtration performance and fabric appearance, to meet the needs of various users.Pulse Valve Controller

The pulse valve controller, which can ensure the stable and reliable work of the bag filter in the harshest industrial environment, can completely replace the PLC control to achieve the dust removal control of the dust collector.