Anode Filter Bag

What Are Anode Filter Bags and Why Are They Crucial?

Anode filter bags are specialized filtration components used extensively in electroplating, metal finishing, and various industrial processes. Their primary function is to capture and remove solid impurities, such as anode slime, debris, and particulates, from plating baths and other chemical solutions. This ensures consistent solution purity, improves plating quality, reduces defects, and protects valuable equipment from damage. By maintaining a clean bath, anode filter bags significantly extend the life of the chemical solution and enhance overall process efficiency.

Key Features and Benefits of Our Anode Filter Bags

Our anode filter bags are engineered for superior performance, durability, and reliability in demanding industrial environments. They are designed to meet the highest standards of filtration efficiency and chemical resistance.

- High Filtration Efficiency: Capable of capturing fine particles to maintain solution clarity and product quality.

- Excellent Chemical Resistance: Compatible with a wide range of acids, alkalis, and other aggressive chemicals commonly used in electroplating.

- Thermal Stability: Withstands high operating temperatures without degradation of the filter material.

- Durable Construction: Reinforced seams and robust materials prevent tearing and failure under pressure.

- Optimized Flow Rates: Designed to allow for efficient fluid passage while maintaining high dirt-holding capacity.

- Easy to Install and Replace: Simplifies maintenance and reduces downtime in your production process.

Detailed Product Specifications

Our anode filter bags are available in various sizes and materials to suit different application requirements. Below are the standard specifications for our most popular models.

| Model Number | Material | Filtration Rating (Microns) | Recommended Max Temperature (°C) | Standard Size (Inches) | pH Range |

|---|---|---|---|---|---|

| AFB-PP-01 | Polypropylene | 1, 5, 10, 25 | 100 | 7 x 16 | 1 - 14 |

| AFB-NMO-02 | Nylon Monofilament | 10, 25, 50, 100 | 120 | 7 x 16, 8 x 18 | 4 - 11 |

| AFB-PES-03 | Polyethersulfone | 0.5, 1, 5 | 130 | 7 x 16 | 1 - 12 |

| AFB-PTFE-04 | PTFE (Teflon) | 1, 5, 10 | 260 | 7 x 16, 8 x 18 | 0 - 14 |

Material Selection Guide

Choosing the correct filter bag material is critical for compatibility with your specific chemical solution and operating conditions.

- Polypropylene (PP): Excellent general-purpose choice. Offers good chemical resistance to most acids and alkalis. Cost-effective.

- Nylon: Provides high strength and abrasion resistance. Best for alkaline solutions. Avoid strong acids.

- Polyethersulfone (PES): Ideal for applications requiring high purity and thermal stability. Excellent for aggressive chemicals.

- PTFE (Teflon): The most chemically inert material. Suitable for the most aggressive chemicals and highest temperatures. Premium performance.

Typical Applications and Industries

Anode filter bags are indispensable in numerous industrial sectors where solution purity is paramount.

- Electroplating and Electrorefining

- Printed Circuit Board (PCB) Manufacturing

- Metal Finishing and Anodizing

- Chemical Processing

- Water and Wastewater Treatment

- Pharmaceutical and Food Processing (where applicable)

Installation and Maintenance Best Practices

Proper installation and maintenance are key to maximizing the performance and lifespan of your anode filter bags.

- Ensure the filter housing is clean and free from old debris before installing a new bag.

- Select the appropriate micron rating based on the level of filtration required for your process.

- Confirm chemical compatibility between the bag material and your process solution.

- Monitor pressure differentials across the filter. A significant increase indicates the bag is full and needs replacement.

- Establish a regular replacement schedule based on your specific operating conditions to prevent breakthrough and process contamination.

- Always handle used filter bags according to local environmental and safety regulations for waste disposal.

Hot Products

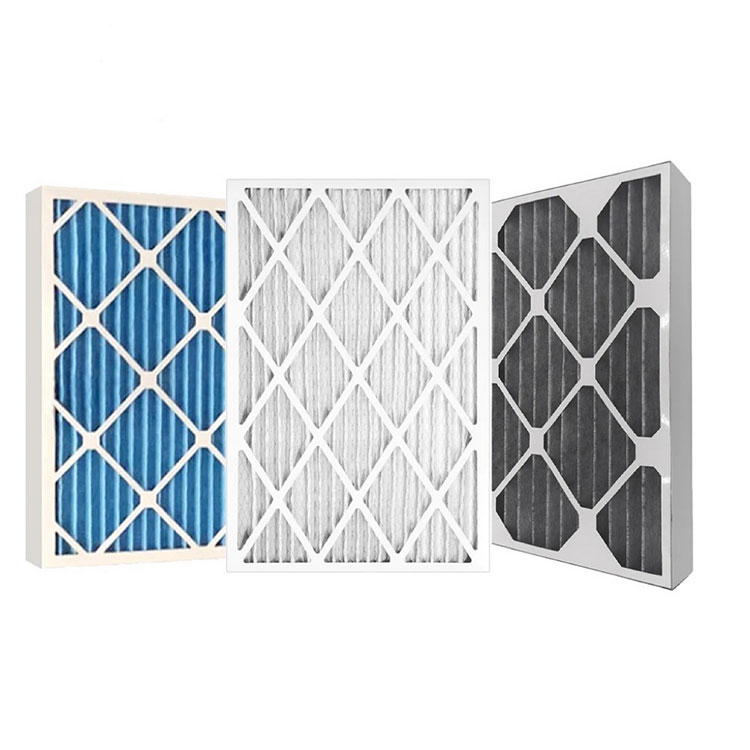

Pharmaceutical Filter Cloth

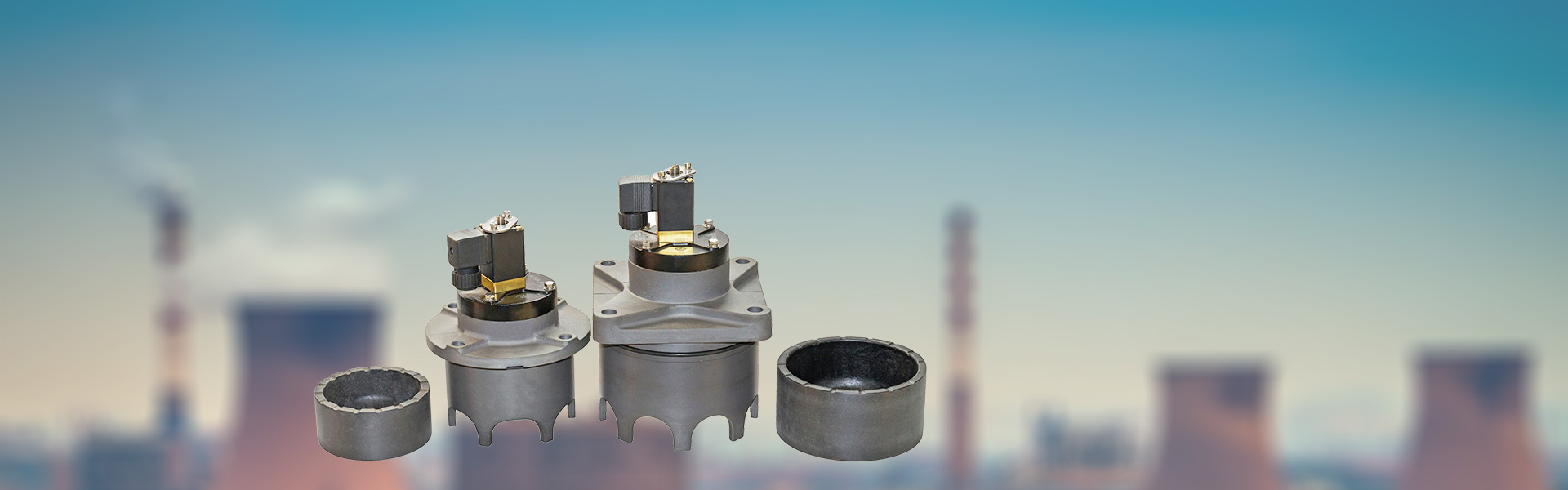

The Pharmaceutical filter cloth made of materials such as polypropylene, polyester, nylon, vinylon, cotton, and non-woven fabrics. We can also use other different raw materials (nylon, chloroprene, vinylon, etc.) to process specialized pharmaceutical air filtration clean filter cloth according to the characteristics of the materials provided by customers and the different usage environments, to meet their different needs.RCA3D1 Pulse Valve

RCA3D1 pulse valve is a new model type of remote control pulse valve, and has 4 types solenoid coil that suitable for different working environments. The valve uses standard imperial threads.Polypropylene Filter Cloth

Wholesale top quality Polypropylene filter cloth from Qingdao Star Machine,it is a common filter media material, made of polypropylene fiber. It has good physicochemical properties, such as corrosion resistance, acid resistance, alkali resistance, wear resistance and temperature resistance, making it suitable for a variety of applications.Tank Bulkhead Connector

TANK BULKHEAD CONNECTOR is used to connect the input end of the pulse valve to the tank. No welding required, easy installation and disassembly, reducing labor costs. SMCC are committed to the bag dust collector accessories industry, provide various types of bulkhead connector and pulse jet valves of the pulse jet baghouse.Split Collar Filter Bag Cage

Qingdao Star Machine can provided high quality Split Collar Filter Bag Cage, we are a Chinese manufacture and supplier who based on filtration decades ago. With excellent quality and long service life, our split collar filter bag cage can be customised to meet any of your filtration system's needs.DC24V 4 Inch Aluminium Pulse Solenoid Valve

Qingdao Star Machine is a professional manufacturer of DC24V 4 inch Aluminium Pulse Solenoid Valve for industrial air dust collector with rich producing and for 20 years and exporting experience to more than 30 countries with strong technical support, competitive price, good quality and 7*24 hours after-sales services.