Chemical Resistant Filter Bags

In demanding industrial environments where aggressive chemicals are present, standard filtration solutions often fall short, leading to equipment degradation, contamination, and frequent, costly replacements. Our specialized Industrial Ore Leaching Filter Bags are engineered specifically to confront these severe operational conditions. For applications requiring resilience against highly acidic or alkaline liquors, our Corrosion Resistance Ore Leaching Filter Bag provides a robust barrier, ensuring the integrity of your filtration process. When thermal stability is paramount, especially in high-temperature leaching circuits, the High Temperature Resistance Ore Leaching Filter Bag maintains its structural and filtering properties without compromise. Furthermore, for processes involving abrasive slurries and particulate matter, our Wear Resistance Ore Leaching Filter Bag offers exceptional durability, significantly extending service life and reducing operational downtime. This comprehensive range is designed to deliver superior performance, maximum contaminant removal, and long-term reliability.

The Chemical Resistant Filter Bags are a culmination of advanced material science and precision engineering. They are constructed from a selection of high-performance polymers and treated fabrics capable of withstanding prolonged exposure to a wide spectrum of harsh chemical agents. The design focuses on achieving optimal filtration efficiency while providing a reliable, long-lasting solution that minimizes maintenance frequency and total cost of ownership. Key technical parameters are detailed below to illustrate the product's capabilities.

- Material Composition: Premium-grade polypropylene, polyester, Nomex, Ryton, or PTFE felt, selected based on specific chemical compatibility.

- Filtration Rating: Ranging from 1 micron to 200 microns to suit various particulate retention requirements.

- Operating Temperature Range: Capable of continuous operation from -40°F (-40°C) up to 500°F (260°C), depending on the base material.

- Seam Construction: Utilizes advanced heat-sealing or specialized sewing techniques with chemically inert thread to prevent seam failure and bypass.

- Surface Treatment: Options include singeing, calendering, or membrane lamination to enhance surface release properties and cake discharge.

| Material Type | pH Resistance Range | Max Continuous Temperature | Key Chemical Resistances |

|---|---|---|---|

| Polypropylene | 1 - 14 | 195°F (90°C) | Acids, alkalis, solvents |

| Polyester | 5 - 9 (weak acids/alkalis) | 275°F (135°C) | Aliphatic hydrocarbons, oxidizing agents |

| Nomex (Aramid) | 5 - 9 (weak acids/alkalis) | 400°F (204°C) | Hydrocarbons, mild acids |

| Ryton (PPS) | 1 - 13 | 375°F (190°C) | Strong acids, alkalis, organic solvents |

| PTFE (Teflon) | 0 - 14 | 500°F (260°C) | Virtually all industrial chemicals |

Hot Products

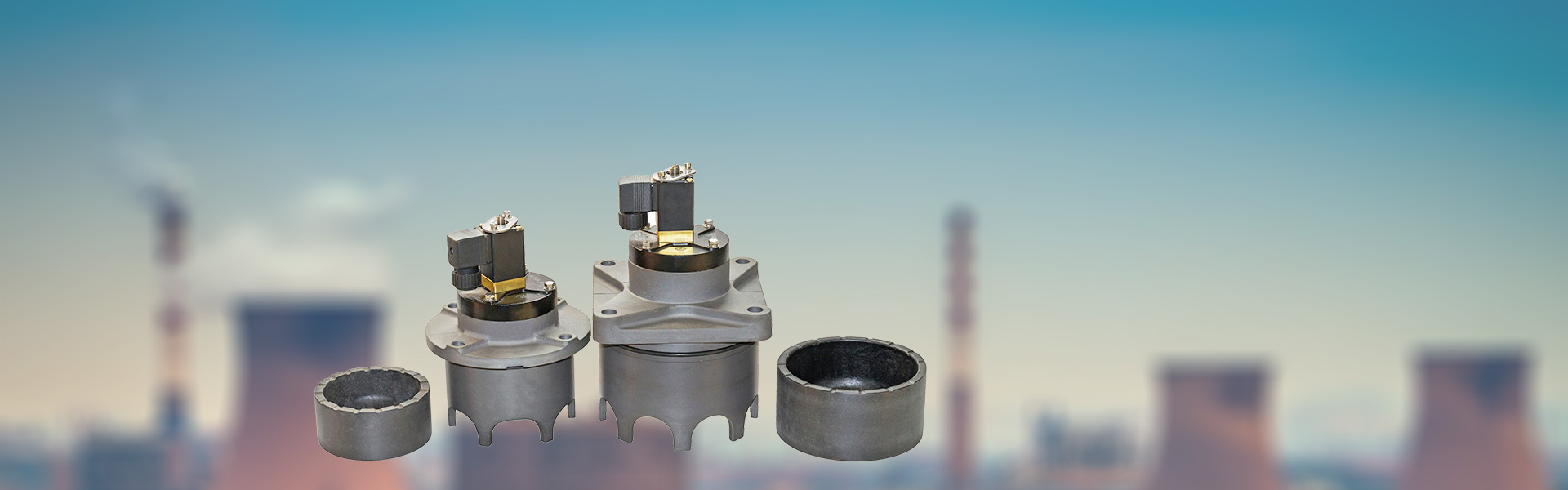

Tank Bulkhead Connector

TANK BULKHEAD CONNECTOR is used to connect the input end of the pulse valve to the tank. No welding required, easy installation and disassembly, reducing labor costs. SMCC are committed to the bag dust collector accessories industry, provide various types of bulkhead connector and pulse jet valves of the pulse jet baghouse.Split Collar Filter Bag Cage

Qingdao Star Machine can provided high quality Split Collar Filter Bag Cage, we are a Chinese manufacture and supplier who based on filtration decades ago. With excellent quality and long service life, our split collar filter bag cage can be customised to meet any of your filtration system's needs.24V DC DMF Solenoid Coil

The 24V DC DMF solenoid coil is wound with enamelled wire on a hollow cylindrical bone, the outer surface of which is injection moulded through the coil assembly. The plug is exposed after the coil and can be connected to the junction box as required, generating magnetic force when energised. The coil is currently widely used in the solenoid valve industry.PP PE Liquid Filter Bags

Qingdao Star Machine Technology Co.,Ltd. Customized PP PE Liquid Filter Bags mainly includes polyester filter bag, PP filter bag, Nylon filter bag, etc.Flakt Membrane Kit

Qingdao Star Machine is a professional manufacturer and supplier of Flakt Membrane Kit, dedicated to providing our customers with excellent de-dusting valves and valve fittings. We can customise the sets according to your requirements and offer a variety of configurations, including diaphragm, diaphragm and small diaphragm, diaphragm and small diaphragm and spring and so on. Upholding high quality standards, we have long-term stable customers in Europe and the United States, ready to provide you with the best customer support.Dust Removal Pulse Solenoid Valve

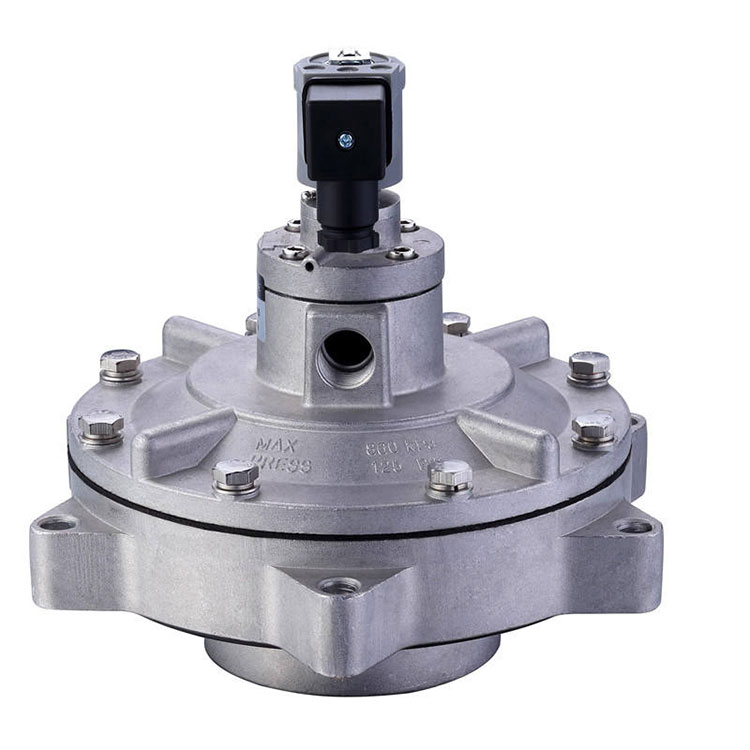

Qingdao Star Machine, as a professional manufacturer Dust Removal Pulse Solenoid Valve, achieving a 98.6% customer repurchase rate in the field of industrial dust control. Our Dust Removal Pulse Solenoid Valve has great function, and can be used in severe environments.