High Temperature Resistance Ore Leaching Filter Bag

In demanding mining and chemical processing environments, selecting the right filtration media is critical for operational efficiency and cost management. High temperature resistance ore leaching filter bags are engineered specifically to withstand the aggressive conditions present during metal extraction and chemical separation processes. These specialized bags offer superior performance compared to standard filtration solutions. For applications requiring robust industrial filtration, our Industrial Ore Leaching Filter Bag provides a reliable foundation. However, the unique challenge of high-temperature, corrosive acidic or alkaline environments necessitates a product with enhanced material properties. Our Chemical Resistant Filter Bags are formulated to resist chemical degradation, ensuring longevity. Complementing this, our Corrosion Resistance Ore Leaching Filter Bag offers exceptional protection against pitting and erosion from harsh leachates. Furthermore, to handle the abrasive nature of ore slurries, our Wear Resistance Ore Leaching Filter Bag is designed to minimize material loss and extend service life. The high temperature resistance variant integrates these properties, creating a comprehensive solution for the most challenging filtration tasks.

The High Temperature Resistance Ore Leaching Filter Bag is constructed from advanced synthetic fibers that maintain structural integrity and filtration efficiency even when exposed to sustained high temperatures. This is crucial in processes like pressure oxidation or high-temperature leaching, where standard filter media would rapidly fail. The key features that define this product include its ability to operate continuously in elevated thermal conditions, its high dirt-holding capacity, and its excellent cake release properties, which facilitate efficient cleaning cycles and reduce downtime.

- Material Composition: High-performance polyphenylene sulfide (PPS) or Aramid fibers.

- Maximum Continuous Operating Temperature: Up to 190°C (374°F).

- Peak Temperature Resistance: Can withstand short-term exposure up to 220°C (428°F).

- Filtration Efficiency: Capable of capturing particles down to 1 micron.

- Standard Sizes: Customizable lengths and diameters to fit all major filter press and bag house systems.

- Surface Treatment: Special glazing or calendaring for enhanced surface release.

| Parameter | Specification | Test Standard |

|---|---|---|

| Air Permeability | 5-15 CFM/ft² | ASTM D737 |

| Bursting Strength | ≥ 500 psi | ASTM D3786 |

| Tensile Strength (Warp) | ≥ 220 lb/in | ASTM D5035 |

| Tensile Strength (Weft) | ≥ 210 lb/in | ASTM D5035 |

| pH Resistance Range | 1 - 14 | Internal Test Method |

| Weight | 14 - 18 oz/yd² | ASTM D3776 |

Hot Products

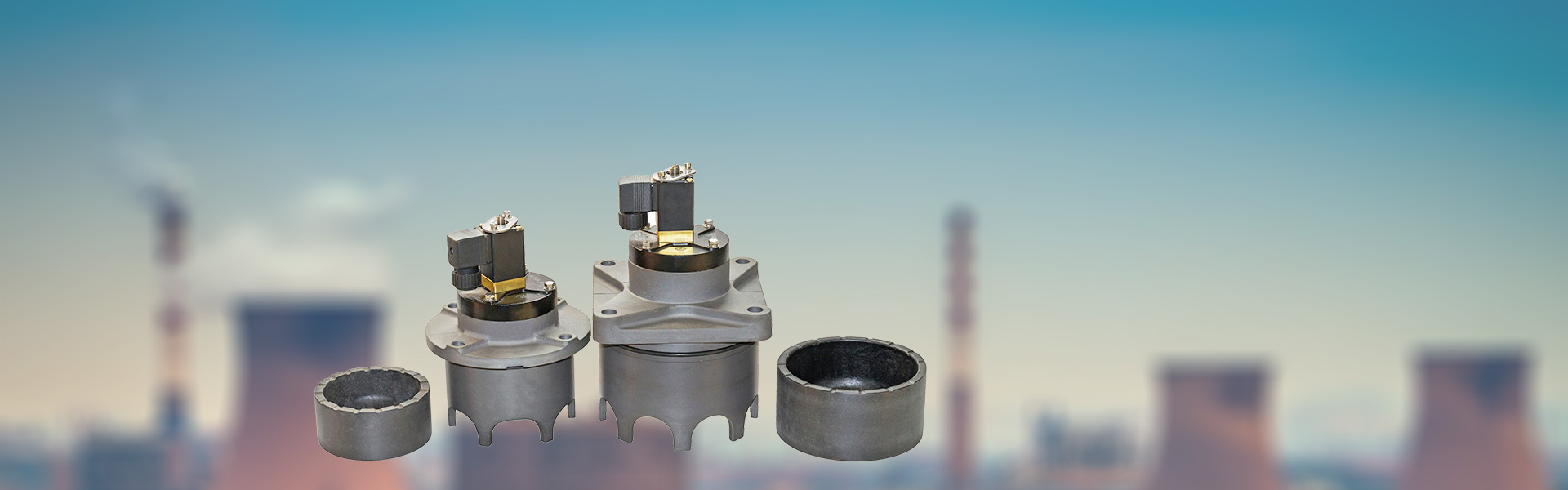

Dust Removal Filter Bag Skeleton

The dust removal filter bag skeleton is the rib of the filter bag, which is lightweight, easy to install and maintain. The quality of the dust removal filter bag skeleton directly affects the filtration status and service life of the filter bag. Starmachinechina introduces dust removal bag framework manufacturing equipment and uses high-frequency welding machines to weld the framework in one go. The dust removal filter bag skeleton is made of iron wire or stainless steel wire with sufficient strength and rigidity. Treatment methods is such as galvanization, spray molding, and organic silicon plating. The dust removal filter bag skeleton processed by Starmachinechina using organic silicon technology can completely replace the stainless steel skeleton, greatly reducing the maintenance cost of the equipment. And each frame manufactured can meet the requirements of being lightweight, smooth, and straight. The annual production capacity is 2 million units, which can meet the urgent supply needs of customers.Dewatering Filter Bag

Dewatering bags (also called dewatering filter bags or sediment filter bags) are an effective, economical solution for filtering sediment, oil, and debris from pumped water.Normal Pressure Bulkhead Connector

NORMAL PRESSURE BULKHEAD CONNECTOR is used to connect the input end of the pulse valve to the tank. The normal pressure pipe is made of steel and can be welded to the tank. SMCC are committed to the bag dust collector accessories industry, provide various types of bulkhead connector and pulse jet valves of the pulse jet baghouse.Solid-Liquid Filter Bag

Qingdao Star Machine Technology Co.,Ltd. is a professional manufacturer and strong supplier of filter bags in China. The Solid-Liquid Filter Bag used in our production process have excellent chemical stability and heat resistance, making them the highest performing representative of the filter material industry and the most high-end variety among all commonly used filter materials. The liquid filter bag adopts advanced hot melt bonding technology to ensure the best bonding strength of the filter bag and prevent leakage.Screen Printing Nylon Filter Mesh

Qingdao Star Machine Screen Printing Nylon Filter Mesh is made from high-strength nylon and polyester material. This series of products has acid resistance, alkali resistance, hydrolysis resistance, and mold resistance. The Filtration of pickled food particles filter cloth can choose different specifications of raw material combinations and different organizational structures, forming various products with different filtration performance and fabric appearance, to meet the needs of various users.Pulse Valve Controller

The pulse valve controller, which can ensure the stable and reliable work of the bag filter in the harshest industrial environment, can completely replace the PLC control to achieve the dust removal control of the dust collector.