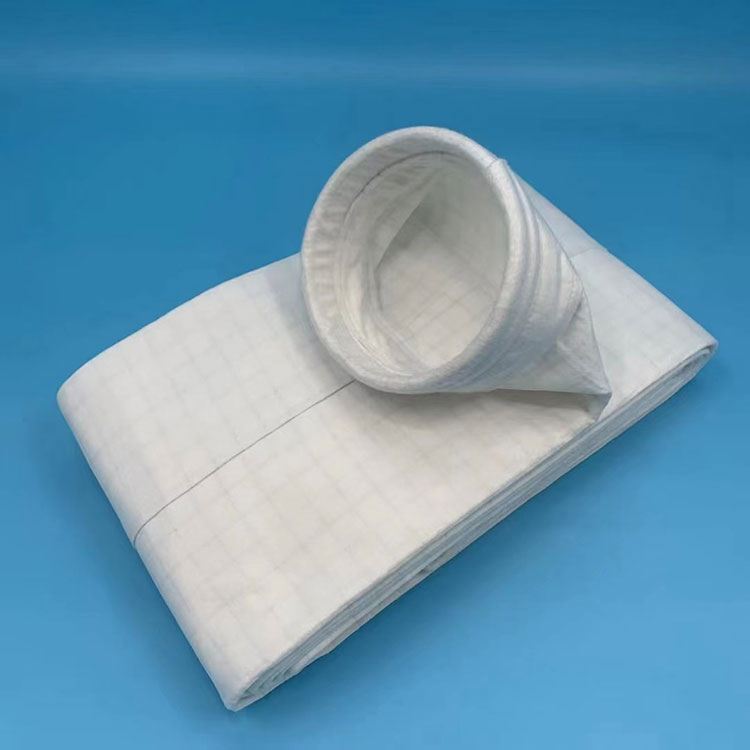

Wear Resistance Ore Leaching Filter Bag

When processing ores in demanding industrial environments, the need for durable and efficient filtration is critical. An Industrial Ore Leaching Filter Bag is engineered to withstand the abrasive nature of slurry mixtures, ensuring consistent performance and protecting downstream equipment. In aggressive chemical leaching circuits, standard filter media can quickly degrade, leading to frequent replacements and operational downtime. Our specialized Chemical Resistant Filter Bags are constructed from advanced polymers that resist a wide range of acidic and alkaline solutions, maintaining their structural integrity and filtration efficiency. For applications where chemical attack is a primary concern, our Corrosion Resistance Ore Leaching Filter Bag offers superior protection against pitting, cracking, and swelling caused by harsh reagents. Furthermore, many leaching processes operate at elevated temperatures, which can compromise the physical properties of filter media. Our High Temperature Resistance Ore Leaching Filter Bag is specifically designed to handle these thermal stresses without loss of filtration capability or dimensional stability.

The Wear Resistance Ore Leaching Filter Bag is defined by its precise technical specifications, which are tailored for maximum longevity and filtration accuracy in ore processing. The core of its performance lies in the material composition, construction method, and physical properties designed to endure extreme conditions. Below are the detailed product parameters presented in both a list and a table for clarity.

Key Features of the Wear Resistance Ore Leaching Filter Bag:

- Material Construction: Multi-layered composite fabric with a tightly woven surface layer and a supportive scrim backing.

- Primary Filter Media: High-tenacity polypropylene felt with a specialized surface treatment.

- Seam Construction: Ultrasonically welded seams to prevent particle bypass and thread unraveling.

- Surface Finish: Calendared and singed surface for improved cake release and reduced blinding.

- Maximum Operating Temperature: Continuous operation up to 210°F (99°C).

- Chemical Compatibility: Resistant to most inorganic acids, alkalis, and solvents within a pH range of 1-12.

- Abrasion Resistance: Excellent resistance to particulate scouring, tested to withstand over 1,000,000 cycles in a standardized Taber Abrasion test.

| Parameter | Specification | Test Standard |

|---|---|---|

| Filtration Rating | 1, 5, 10, 25 Micron (custom available) | ASTM F795 |

| Air Permeability | 10-15 CFM/ft² | ASTM D737 |

| Burst Strength | > 500 psi | ASTM D3786 |

| Weight | 16 oz/yd² | ASTM D3776 |

| Tensile Strength (Warp x Fill) | 300 lbf x 280 lbf | ASTM D5035 |

| Mullen Burst | 450 psi (minimum) | ASTM D3786 |

| Recommended Max Pressure Drop | 15 psi | - |

Hot Products

Crop Fertilization Filter Cloth

Qingdao Star Machine is a professional manufacturer of Crop fertilization filter cloth and other series of products. The products mainly include polypropylene, polyester, nylon, and vinylon woven monofilament filter fabrics, and multifilament filter fabrics; Room temperature and high temperature air dust removal and filtration materials.Our company is a high-tech enterprise that integrates research and development, production, sales, and after-sales service, focusing on liquid filtration and filtration products. Our Filter sells not only filtration products, but also comprehensive solutions to filtration technology problems.Piston Type Pulse Solenoid Valve

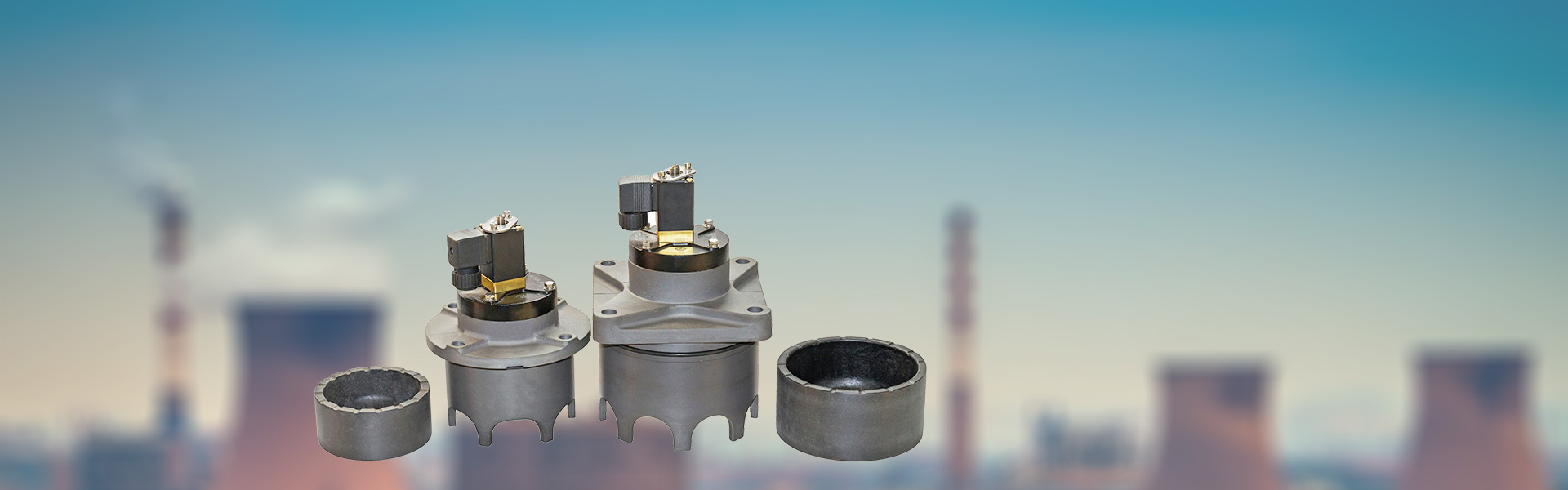

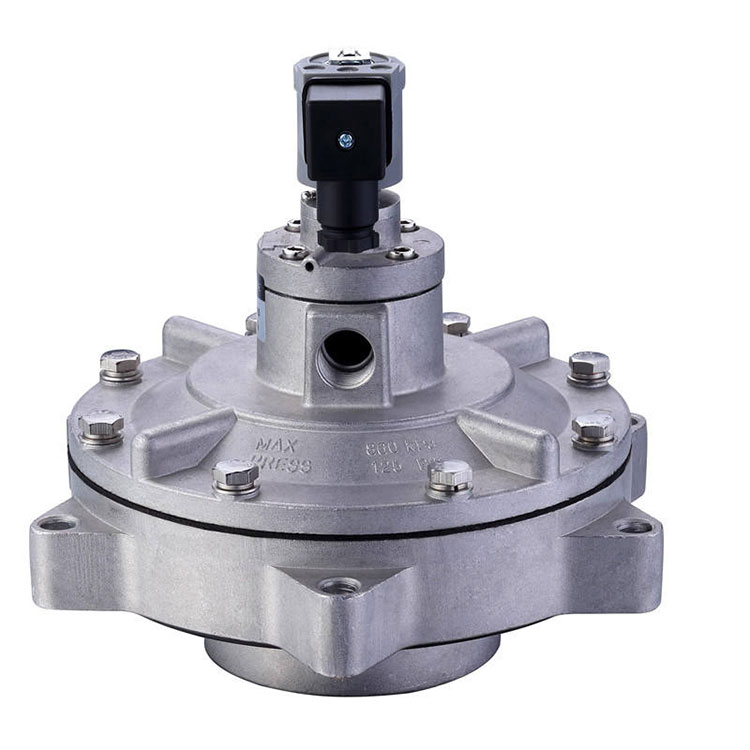

Qingdao Star Machine Technology Co., Ltd. is a modern scientific and technological manufacturer integrating R&D, production, sales and service, specializing in the production of various types of piston type pulse solenoid valve, pneumatic components and fluid control equipment. The company has a high-quality R & D team and advanced production equipment, with exquisite technology, rigorous quality management system, and constantly provide customers with quality products and services at competitive price.Fluid Bed Dust Bag

Qingdao Star Machine’s high quality Fluid Bed Dust Bag is a crucial component in the drying and granulation process. It is typically made of woven polyester or polyester silk cloth and treated with stitching and sealing technology to ensure a smooth and flat surface. The Fluid Bed Dust Bag offers low resistance, good air permeability, and can resist adhesion, making it effective in capturing powder. We can create custom sizes such as 16, 18, or 24 fingers based on your needs. Alternatively, we can produce according to your provided samples.CA/RCA45DD Pulse Valve

As the professional manufacturer, we would like to provide you high quality CA/RCA45DD Pulse Valve. At Qingdao Star Machine, we specialize in delivering high-quality pulse jet valves that serve as cost-effective replacements for Goyen series valves. Our range features options like the DD series, T series, and MM series. We also provide spare parts and diaphragm replacements to meet all your maintenance needs.Pulse Valve Pilot Cover

Qingdao Star Machine Pulse valve pilot cover V3630501-0100 is a high-quality aluminum alloy accessory designed specifically for the Starmachinechina series of pulse solenoid valves. It has the advantages of simple structure, beautiful appearance, light weight, low cost, durability, and durability.Industrial Circulating Water Filter Bag

Qingdao Star machine leads the way in wastewater filtration solutions, supplying high quality Industrial circulating water filter bag, emphasizing environmental care and filtration excellence. Our top-tier Industrial circulating water filter bag is meticulously crafted to provide customers with outstanding filtration performance, contributing to a cleaner and greener future.