Industrial Ore Leaching Filter Bag

In the demanding field of industrial ore leaching, selecting the right filtration equipment is critical for operational efficiency and cost management. Our specialized range of filter bags is engineered to withstand the harsh chemical and physical environments of leaching processes. For applications involving aggressive solvents and acids, our Chemical Resistant Filter Bags provide an impermeable barrier, ensuring the integrity of the filtration system. A primary challenge in this sector is material degradation due to corrosive agents; our Corrosion Resistance Ore Leaching Filter Bag is specifically designed to combat this, offering long-lasting performance and reducing downtime. Many leaching operations involve elevated temperatures, which is why our High Temperature Resistance Ore Leaching Filter Bag is constructed from advanced materials that maintain structural integrity and filtration efficiency under thermal stress. Furthermore, the abrasive nature of ore slurries demands exceptional durability, a quality inherent in our Wear Resistance Ore Leaching Filter Bag, which is built to resist particle abrasion and extend service life significantly. These products represent a comprehensive solution for modern mineral processing needs.

The Industrial Ore Leaching Filter Bag is the result of extensive research and development, incorporating feedback from leading mining and metallurgical operations worldwide. It is designed as a robust, high-performance component for solid-liquid separation in aggressive leaching circuits. The construction of the Industrial Ore Leaching Filter Bag focuses on precision engineering to handle high flow rates while capturing fine particulates, ensuring a clear filtrate and maximizing valuable metal recovery. The bag's design minimizes blinding and allows for efficient cake release, which simplifies maintenance and cleaning procedures. By utilizing the Industrial Ore Leaching Filter Bag, operations can achieve higher throughput, consistent filtration quality, and a lower total cost of ownership. Its compatibility with various standard and custom filter housing systems makes it a versatile choice for both new installations and retrofitting existing equipment.

- Material Composition: Premium polypropylene, polyester, Nomex, Ryton, or PTFE felt, selected based on application-specific chemical and thermal requirements.

- Filtration Rating: Available from 1 micron to 200 microns, providing precise particle retention.

- Maximum Operating Temperature: Ranges from 150°F (66°C) for standard synthetics to 500°F (260°C) for high-temperature specialty fibers.

- Burst Strength: Exceeds 500 psi, ensuring bag integrity under high differential pressure.

- Seam Construction: Ultrasonically welded or heat-sealed seams for maximum strength and no media bypass.

- Standard Sizes: Compatible with most common housing designs, including 7" O.D. x 17", 32", 48", and 84" lengths.

| Filter Bag Type | pH Resistance Range | Max Continuous Operating Temp | Recommended Application |

|---|---|---|---|

| Polypropylene Standard | 1 - 14 | 180°F (82°C) | General acid/alkali leaching, solvent extraction |

| PTFE Membrane | 0 - 14 | 500°F (260°C) | Highly corrosive and high-temperature oxidative leaching |

| Nomex Felt | 4 - 9 | 400°F (204°C) | High-temperature cyanide or ammonium carbonate leaching |

| Ryton Felt | 1 - 12 | 375°F (190°C) | Abrasive and corrosive slurry applications |

Hot Products

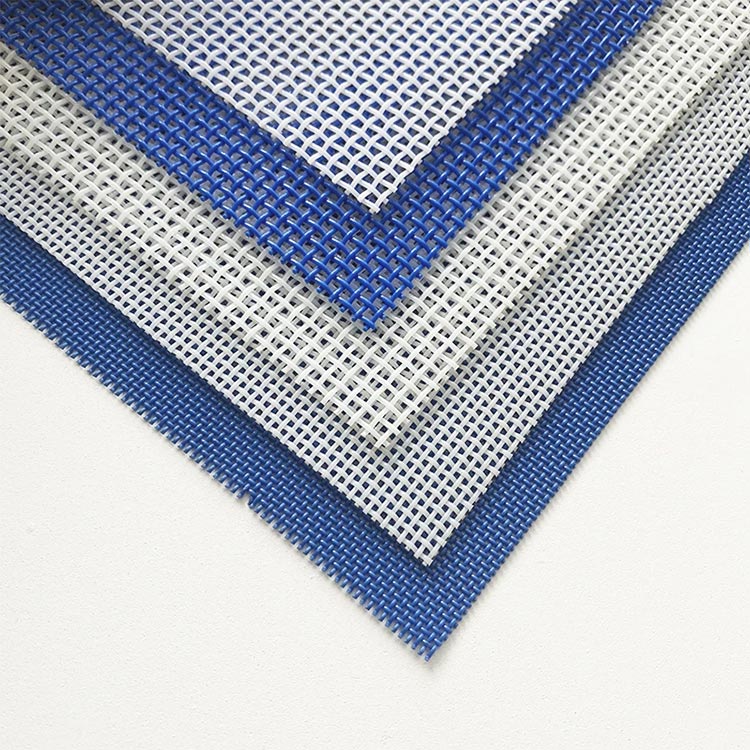

Polyester Linear Screen Cloth

Qingdao Star Machine’s durable Polyester Linear Screen Cloth is an important industrial fabric, which is made of polyester fiber by special weaving process and has a linear mesh structure. This screen cloth has a wide range of applications in many fields, such as chemical, environmental protection, pharmaceutical, food and other industries in the filtration, screening and separation process.For more assured procurement, we can provide samples to test quality.Dresser Nut Valves

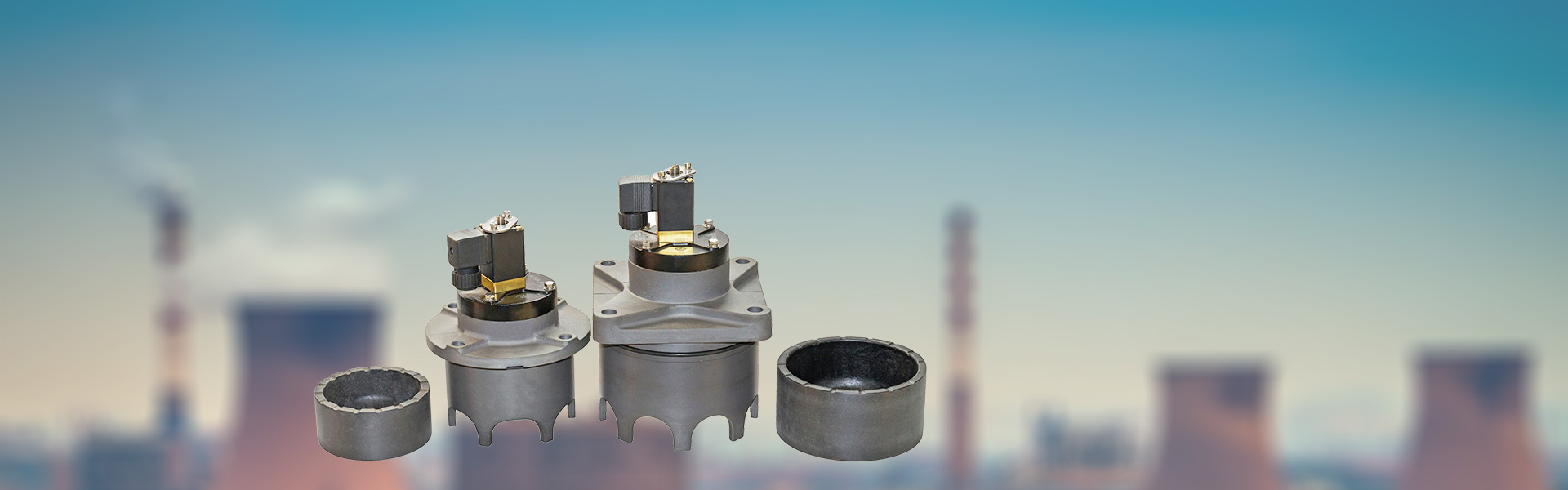

Qingdao Star Machine's Dresser Nut Valves can improve your industrial dust removal processes. Dresser Nut Valves come in various models such as CA20DD, CA25DD, and CA45DD, catering to different industrial needs. Trust in our Dresser Nut Valves for reliable and efficient industrial filtration solutions.Antistatic Dust Filter Bag

Antistatic dust filter bag is the key component of the dust removal system, choose the right specification can improve the efficiency and safety of dust removal. Our filter bag is of good quality, easy to use, long service life.Cotton Filter Cloth

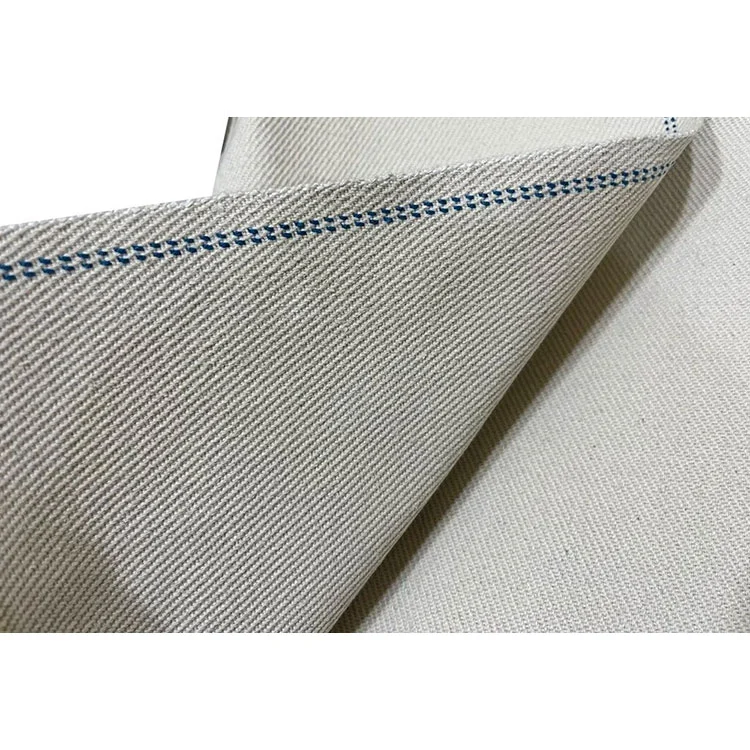

Cotton filter cloth, as a filter cloth made of natural materials, is a good choice for environmental protection because of its easy degradability and other advantages. SMCC can customise cotton filter cloth according to customer requirements in satin, twill and plain weave, and samples can be provided.Edible Oil Filter Cloth

Qingdao Star Machine Technology Co.,Ltd. Is a professional Edible Oil Filter Cloth suppliers in China. Our Edible Oil Filter Cloth is produced from polypropylene or polyester short fibers as the main raw material through processes such as loosening, carding, disordering, mesh laying, and needle punching. This Edible Oil Filter Cloth has superior water permeability, filtration, durability, and other characteristics; It has high tensile strength, tear resistance, and bursting strength mechanical properties. It can be widely used in embankment, soil and water construction, reclamation, environmental protection and other projects, and can play a unique role in engineering.Plunger Pulse Solenoid Air Valve

Plunger pulse solenoid air valve is a dust removal valve that sprays compressed air through a pulse current. It is available in three-inch and four-inch models.