Industrial Anti Static Dust Filter Bag

In industrial settings where combustible dust and fine particulates are present, managing static electricity is a critical safety and operational concern. Our Anti-static Dust Collector Bags are engineered to mitigate this risk effectively. These specialized bags are designed to prevent the buildup of static charges that could lead to sparks, fires, or explosions. For applications demanding superior filtration efficiency and surface filtration, our PTFE Membrane Filter Bag offers an excellent solution, often laminated onto a base fabric for high-temperature and chemically challenging environments. For high-temperature resilience, our Woven Fiberglass Filter Bag provides exceptional dimensional stability and resistance to thermal degradation. In scenarios requiring depth filtration and high dust-holding capacity, our Nonwoven fabric filter Bag is the ideal choice, constructed from needle-felt materials for robust performance. Each of these product lines can be manufactured with integrated anti-static properties to ensure comprehensive protection and operational continuity.

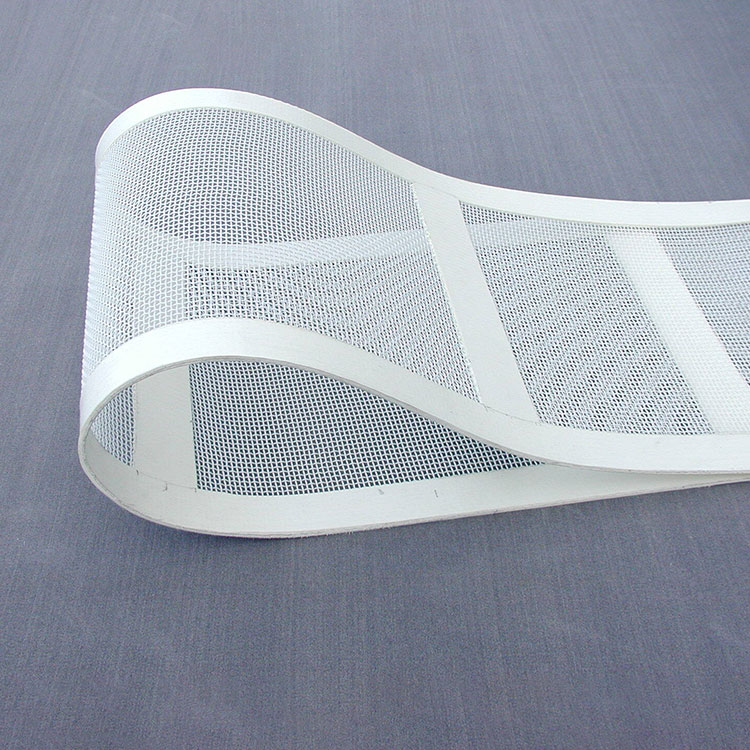

The Industrial Anti Static Dust Filter Bag is manufactured with precision, incorporating conductive elements such as carbon fiber threads or stainless steel wire woven directly into the filter media. This construction creates a continuous path for static electricity to dissipate safely to the grounded bag cage or housing, effectively neutralizing potential ignition sources. The core filtration media is selected based on the specific application, whether it is polyester, polypropylene, Nomex, Ryton, or P84 felt, and is then enhanced with the anti-static feature. These bags are designed for easy installation and maintenance, fitting standard dust collector systems. They are rigorously tested to meet industry standards for electrical conductivity and filtration performance, ensuring reliability in demanding industrial processes like woodworking, pharmaceutical production, metalworking, and chemical processing. The combination of advanced materials and specialized construction makes the Industrial Anti Static Dust Filter Bag a vital component for safeguarding both personnel and equipment.

| Parameter | Specification / Value |

|---|---|

| Material Options | Polyester Felt, Polypropylene Felt, Nomex Felt, Ryton Felt, P84 Felt, Fiberglass Cloth, PTFE Laminated Felt |

| Static Dissipation Method | Inlaid conductive fibers (e.g., carbon, stainless steel) |

| Surface Resistivity | < 10^9 ohms/sq (Meets OSHA/NEPA 77 standards) |

| Operating Temperature Range |

|

| Filtration Efficiency | Up to 99.99% on sub-micron particles (dependent on media and finish) |

| Standard Finishes | Singeing, Calendaring, PTFE Coating, Anti-static Treatment |

| Bag Construction | Circular weaving or needle felting with heat-sealed or sewn seams |

| Available Sizes (Diameter x Length) | Customizable; Common sizes: 5" x 10', 6" x 12', 8" x 12' |

| Air-to-Cloth Ratio Recommendation | Varies by application; Typically 2:1 to 6:1 (ft/min) |

| Applicable Industries | Woodworking, Pharmaceutical, Food & Beverage, Chemical, Metalworking, Power Generation |

| Compliance Standards | OSHA, NFPA 652, NFPA 654, ATEX Directive (for specific models) |

Key Features and Benefits

- Enhanced Safety: Prevents static discharge, reducing the risk of dust explosions and fires in hazardous environments.

- High Filtration Performance: Effectively captures fine and coarse dust particulates, improving air quality and protecting downstream equipment.

- Durable Construction: Made from high-quality, abrasion-resistant materials for extended service life and reduced replacement frequency.

- Wide Compatibility: Designed to fit most major dust collector brands and models, ensuring easy integration into existing systems.

- Customizable Options: Available in various materials, sizes, and finishes to meet specific process requirements and operational conditions.

- Low Maintenance: Excellent cake release properties and anti-static characteristics contribute to stable pressure drop and less frequent cleaning cycles.

- Cost-Effective Operation: Long-lasting filter life and reliable performance help lower overall operational and maintenance costs.

Hot Products

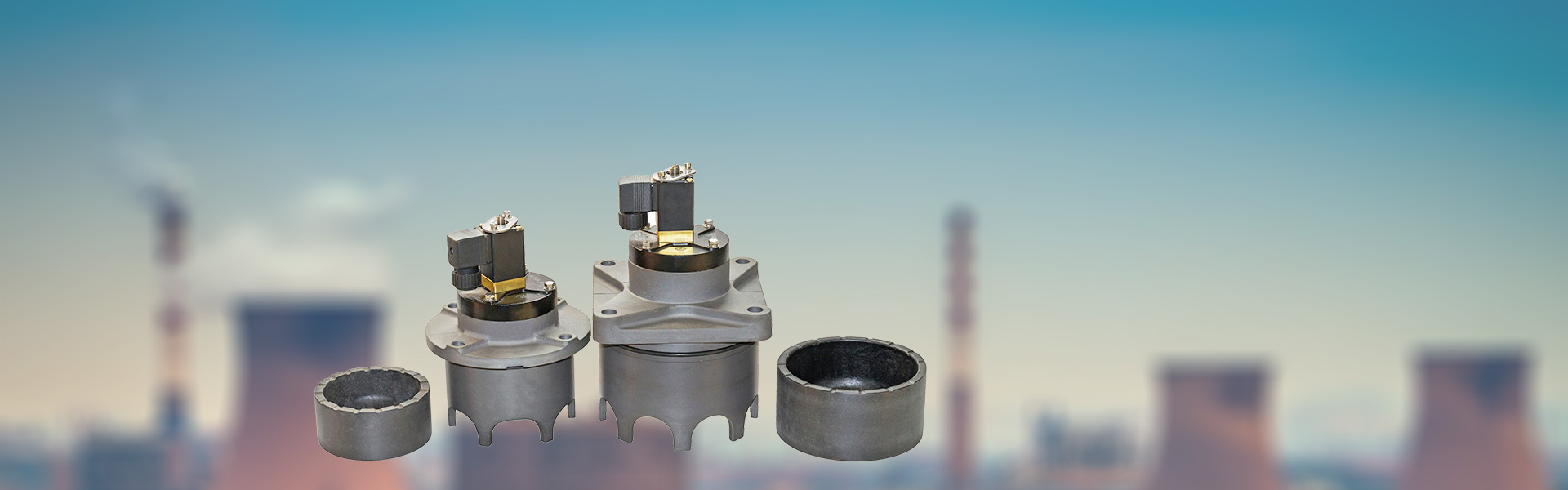

Flanged Diaphragm Valves

Qingdao Star Machine has been in the filtration industry for many years, offering a wide range of high quality dust collection valves, flanged diaphragm valves included. We are committed to the environment and endeavour to contribute to cleaner air while reducing energy consumption.Coupling Set

Qingdao Star Machine provides high quality piston pulse valves and accessories, including coupling set(also know as valve body), valve cover, diaphragm, pilot valve and so on. Our products can be customised according to your specific needs, if you are not sure what products you need to buy, you can contact our engineers to provide selection reference.Beverages and Liquor Filter Bag

Qingdao Star Machine is committed to the cleaning industry and can provide proceed Beverages and Liquor Filter Bag, with efficient filtration solutions to ensure the filtration efficiency of gases and liquids. We focus on product quality, technical support and customer satisfaction. Our team of professional engineers can provide you with valve installation instructions, usage suggestions and solutions.Waste Water Treatment Filter Cloth

Qingdao Star Machine is a professional waste water treatment filter cloth manufacturer and strong supplier in China. Our customized waste water treatment filter cloth mainly including polyester filter cloths, nylon filter cloths, polypropylene filter cloths, vinylon filter cloths, etc. Waste water treatment filter cloth is a component of the filter press, mainly used for solid-liquid separation.Polyester Spiral Filter Belt

SMCC provides high temperature resistant, breathable, food grade safe polyester spiral filter belts with different models to adapt to different environments, suitable for food processing, papermaking, environmental protection and other industries, the products are made of imported materials, durable and with good filtration effect.Rotary Filter Cloth

Wholesale top quality rotary filter cloth from Qingdao Star Machine,it is a special filter cloth, usually used to filter liquids, gases and solids and other substances to prevent impurities in it from polluting the environment. The rotary filter cloth working principle is mainly to support the filter cloth through the rotating mechanism of the fiber turntable filter, so that the liquid to be filtered from the middle of the turntable, through the filtration of the fiber turntable filter cloth, impurities are filtered out, and clean substances are collected.