Nonwoven fabric filter Bag

In industrial filtration systems, selecting the right filter bag is crucial for optimizing performance and maintaining safety. Our range of high-quality nonwoven fabric filter bags offers exceptional filtration efficiency, durability, and customization options to meet diverse industrial needs. As a trusted manufacturer, we provide specialized solutions such as the Industrial Anti Static Dust Filter Bag for environments where static electricity poses risks, ensuring reliable dust collection. For enhanced safety in sensitive applications, our Anti-static Dust Collector Bags are designed to prevent sparking and improve operational stability. Additionally, advanced options like the PTFE Membrane Filter Bag offer superior chemical resistance and high-temperature tolerance, ideal for harsh conditions. For applications requiring robustness and thermal stability, the Woven Fiberglass Filter Bag provides excellent performance in high-heat environments, ensuring long-lasting filtration with minimal maintenance.

The Nonwoven fabric filter bag stands out for its versatility and efficiency, making it a top choice across various industries. Crafted from high-grade synthetic fibers, these bags offer superior dust-holding capacity and consistent performance in demanding settings. Below is a detailed overview of the key parameters and features:

- Material Composition: Made from polypropylene, polyester, or other specialized fibers, ensuring chemical resistance and durability.

- Filtration Efficiency: Capable of capturing particles as small as 1 micron, with high dust release properties for extended service life.

- Temperature Resistance: Operates effectively in temperatures ranging from -40°C to 130°C, depending on the material type.

- Application Areas: Widely used in cement production, pharmaceutical manufacturing, food processing, and chemical industries for air pollution control and product recovery.

- Customization Options: Available in various sizes, shapes, and seam types to fit specific dust collector systems and operational requirements.

To further illustrate the technical specifications, here is a comparative table of common nonwoven fabric filter bag types:

| Type | Material | Max Temperature (°C) | Filtration Efficiency (%) | Common Applications |

|---|---|---|---|---|

| Standard Polypropylene | Polypropylene | 90 | 99.5 | General dust collection, food industry |

| Polyester Felt | Polyester | 130 | 99.9 | Cement, mining, metal processing |

| Anti-Static Variant | Conductive fibers | 120 | 99.7 | Explosive dust environments, pharmaceuticals |

| High-Temperature Option | Fiberglass blend | 260 | 99.8 | Boiler plants, incineration processes |

These parameters ensure that the Nonwoven fabric filter bag delivers reliable performance, reduced downtime, and cost-effective filtration solutions. Regular maintenance and proper installation can further enhance its lifespan, making it an economical choice for industrial applications.

Hot Products

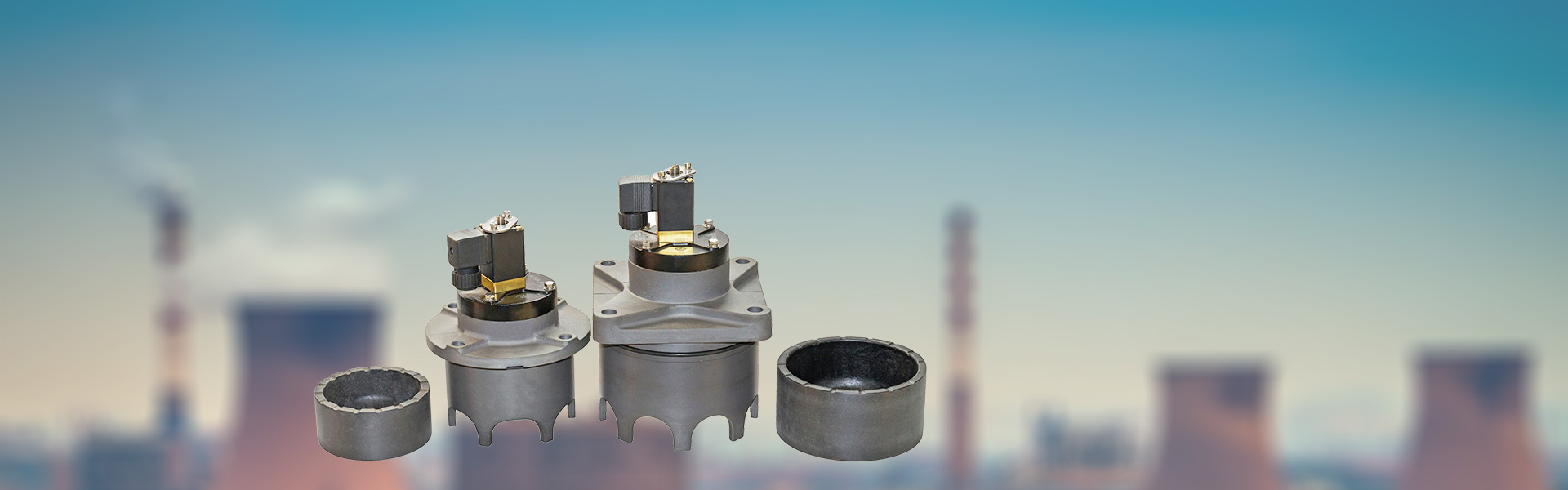

Submerged Dust Collector Valve

Qingdao Star Machine Technology Co.,Ltd. is a large-scale Dust removal Submerged Dust Collector Valve manufacturer and supplier in China.We have over 20 years of production and sales experience in the field of dust removal and purification equipment. We have always adhered to the principle that "reputation and quality are the space for development". Our Submerged Dust Collector Valve covers most markets in Europe, Asia, and the United States. We look forward to becoming your long-term partner in China.Air Dust Removal Filter Bag

Qingdao Star Machine Technology Co.,Ltd. is an Air Dust Removal Filter Bag professional manufacturer and powerful supplier. Our filter bag used in our production process have excellent chemical stability and heat resistance, making them the highest performing representative in the filter material industry and the most high-end variety among all commonly used filter materials. Commonly used filtering materials include PE, PP, PTFE, Cotton, etc.Single Filament Filter Cloth

Wholesale cheap price Single filament filter cloth from Qingdao Star Machine,it is a filter material woven by a single fiber, which has the characteristics of high permeability, high filtration efficiency and long life. It is suitable for continuous production environment, such as alumina, phosphate fertilizer industry, cement, smelting, chemical industry, etc., can greatly improve labor productivity and reduce labor intensity of workers. The fiber structure of the monofilament filter cloth makes it a high filtration efficiency and can effectively remove solid impurities and suspended matter in the liquid.Electromagnetic Diaphragm Valve

Qingdao Star Machine is an Electromagnetic Diaphragm Valve supplier, in the chemical industry, this valve is mainly used for air dust cleaning. As a highly polluting industry, the dusty exhaust gas in the factory is not conducive to environmental protection and sustainable development. The use of dust removal valves can remove dust from the gas and discharge relatively clean air.PP Liquid Filter Bag

The PP liquid filter bag is built to last and works great, making it perfect for industrial use. It has better material properties, so it can capture a wide range of contaminants while keeping the flow rates up. You can customise the options to suit your needs, so each filter bag can be tailored to specific requirements across different industries.Pulse Valve Pilot Cover

Qingdao Star Machine Pulse valve pilot cover V3630501-0100 is a high-quality aluminum alloy accessory designed specifically for the Starmachinechina series of pulse solenoid valves. It has the advantages of simple structure, beautiful appearance, light weight, low cost, durability, and durability.