Anti-static Dust Collector Bags

Anti-static Dust Collector Bags: Essential for Industrial Safety and Efficiency

In industrial environments where combustible dust and static electricity pose significant risks, our Industrial Anti Static Dust Filter Bag is engineered as a critical safety component. For applications demanding superior chemical resistance and high filtration efficiency, our PTFE Membrane Filter Bag provides an exceptional solution. When high-temperature operations are a primary concern, the Woven Fiberglass Filter Bag offers reliable performance and durability. For general-purpose filtration needs with excellent dust release properties, our Nonwoven fabric filter Bag is an economical and effective choice. Each product is designed to mitigate static discharge, enhance filtration, and protect both personnel and equipment.

The core function of an Anti-static Dust Collector Bag is to safely capture fine particulate matter while preventing the accumulation of static electricity, which can lead to sparks and potential explosions in sensitive environments. These bags are integral to dust collection systems across various sectors, including woodworking, pharmaceutical, food processing, and metalworking. By effectively controlling static, the Anti-static Dust Collector Bag ensures consistent system performance, reduces downtime for maintenance, and complies with stringent industry safety standards. Its design focuses on maximizing airflow and dust holding capacity, contributing to a cleaner and safer workplace.

Key Product Parameters

- Material Composition: Premium synthetic fibers with integrated conductive filaments or carbon fiber threads.

- Surface Treatment: Special anti-static finishing to dissipate electrical charge effectively.

- Filtration Efficiency: High efficiency in capturing sub-micron particles, typically exceeding 99.9% for specified sizes.

- Temperature Resistance: Capable of withstanding continuous operating temperatures up to 280°F (138°C), with higher grades available.

- Static Dissipation Rate: Rapid charge dissipation to prevent hazardous static buildup, meeting OSHA and NFPA standards.

- Construction: Robust construction with reinforced seams and options for various cuff styles (e.g., snap band, string).

| Parameter | Specification | Test Standard |

|---|---|---|

| Air-to-Cloth Ratio | 2.5 : 1 to 6 : 1 (CFM/sq.ft) | ASME |

| Basis Weight | 14 - 18 oz/sq.yd | ASTM D3776 |

| Permeability | 15 - 25 CFM/sq.ft | ASTM D737 |

| Surface Resistivity | < 10^9 ohms/sq | ASTM D257 |

| Maximum Pressure Drop | 8 in. w.g. | AMCA 210 |

| Bag Length Options | 48", 60", 72", 84", 96" | Custom |

Hot Products

Nomex Filter Bag

Nomex filter bags (aramid filter bags) can resist high temperatures and keep their shape and stability even when they are as hot as 250°C. This type of filter bag can be used in places like thermal power generation, powder metallurgy or other heavy industries. It is perfect for the most extreme industrial environments.Pulse Valve Controller

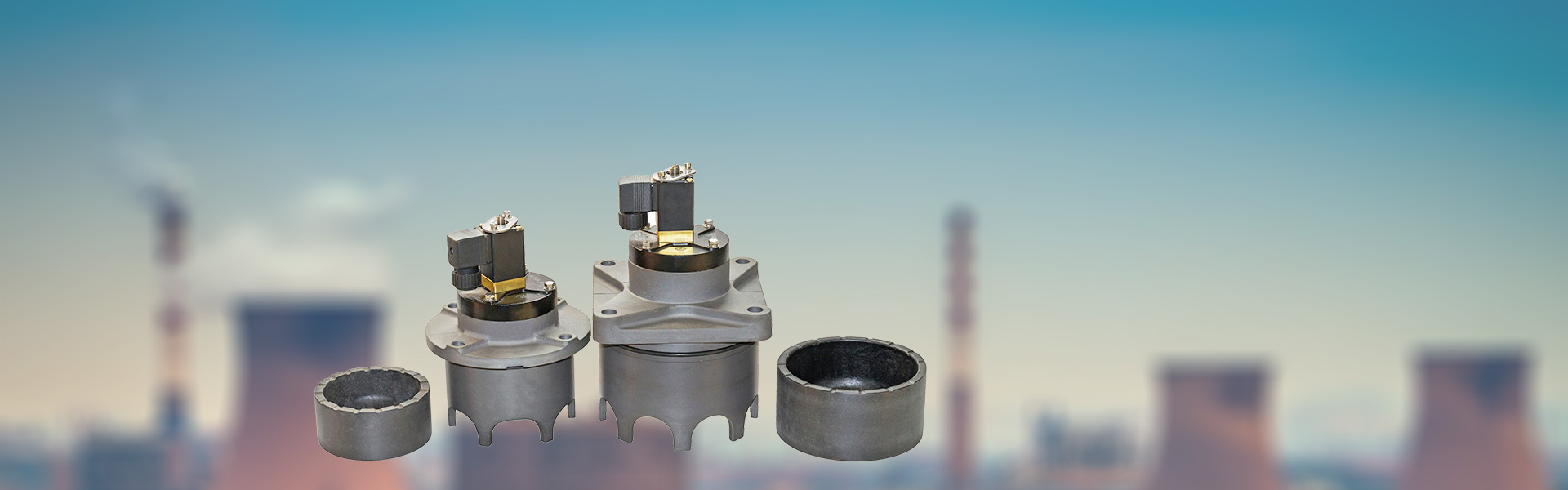

The pulse valve controller, which can ensure the stable and reliable work of the bag filter in the harshest industrial environment, can completely replace the PLC control to achieve the dust removal control of the dust collector.G1 Threaded Pulse Valve

The Qingdao Star Machine G1 Threaded Pulse Valve has an advantages in supply, high quality, low price, fast quotation, short delivery time, and long warranty period.Dust Collector Frame

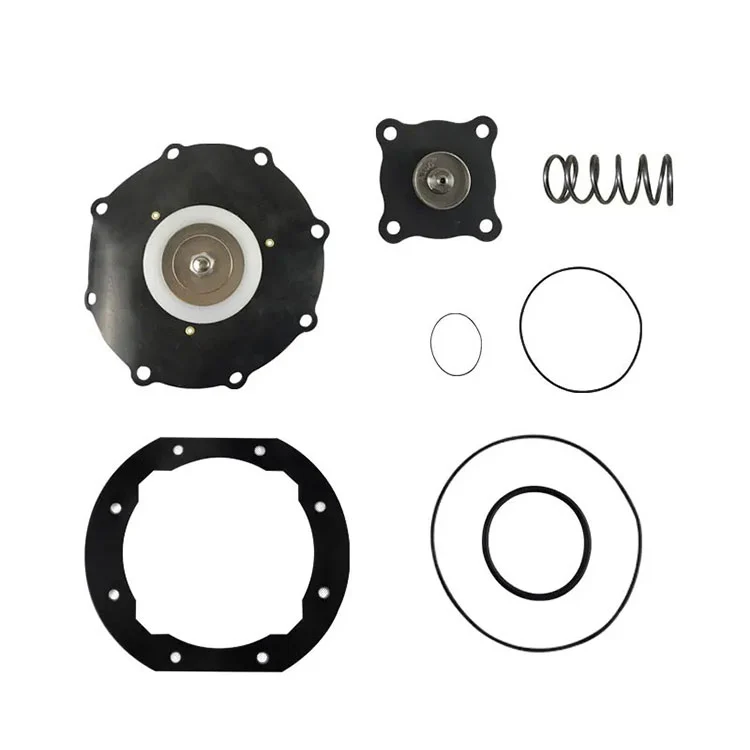

Qingdao Star Machine's low priceDust Collector Frame serves as a crucial component in supporting external filter bags within dust collection systems. Its primary function is to ensure that the filter material remains in a state of tension and maintains a specific shape during the filtration process and ash removal. By providing structural support to the filter bags, the dust collector frame plays a pivotal role in optimizing the efficiency and longevity of the overall dust collection system.C113928 Replacement Kit

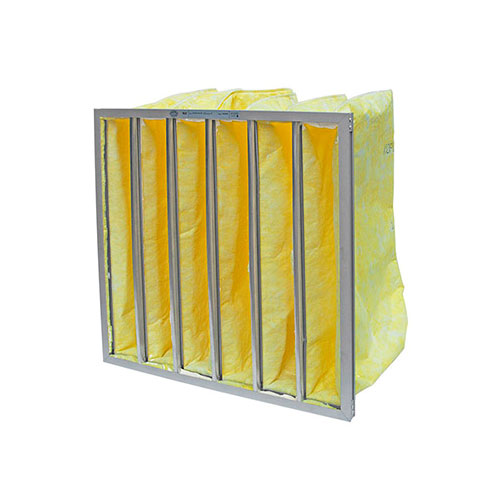

The C113928 Replacement Kit is a diaphragm kit made for Valve SCEX353.060. The repair kit is made from top-quality imported NBR rubber, it makes it easier to blow through the valve and reduces energy loss. It's a solid choice for keeping your ASCO 3-inch submerged pulse valve system in good shape.High Efficiency Pocket Bag Filter

A high efficiency pocket bag filter is an air filter used in HVAC systems, featuring 3 to 12 internal bags. Pocket filters are designed mainly to reduce dust and other airborne particles, effectively filtering out at least 90% of these particles from the air.