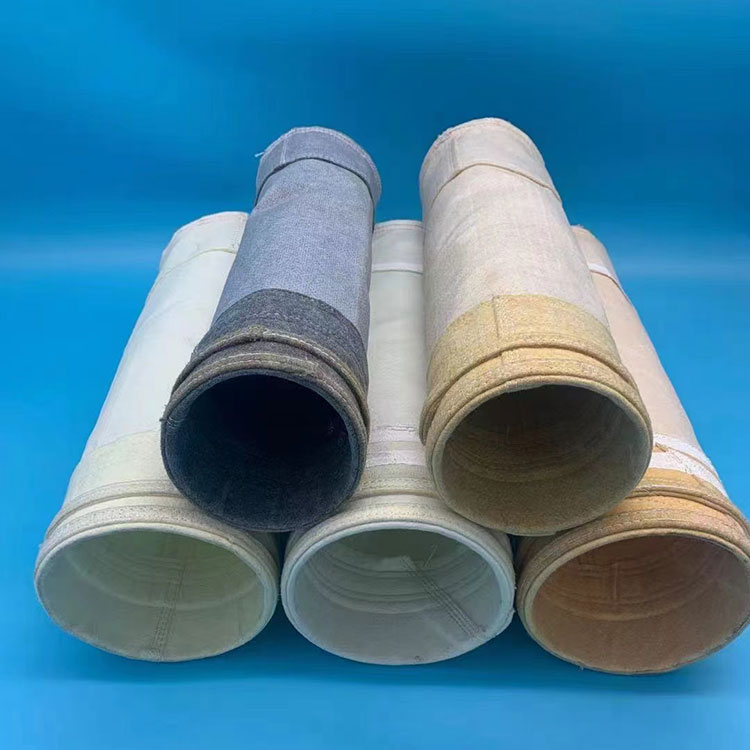

Woven Fiberglass Filter Bag

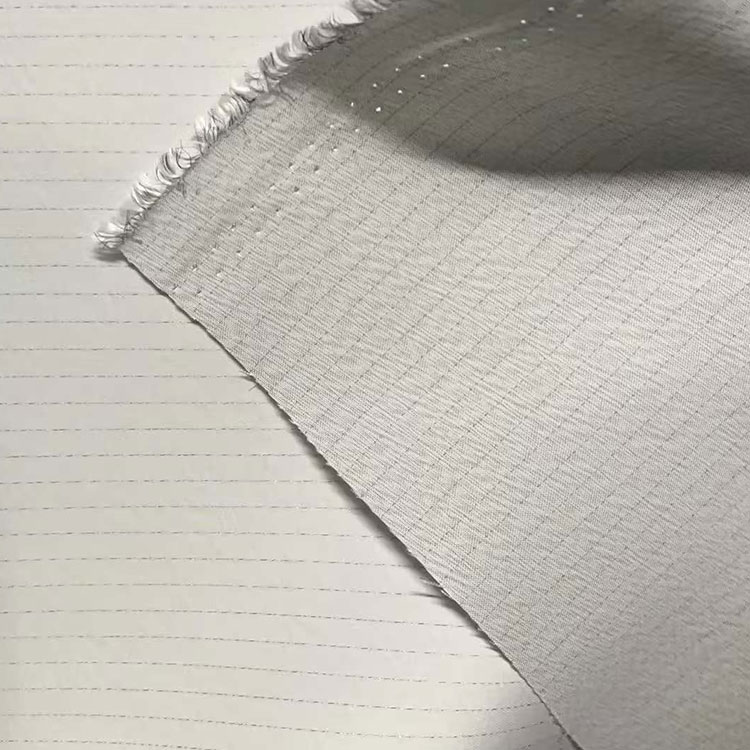

Woven fiberglass filter bags provide outstanding performance in high-temperature and demanding industrial filtration processes. They excel in applications that require exceptional thermal stability, chemical resistance, and dimensional integrity. For environments where static electricity poses a significant risk, we recommend pairing these bags with our Industrial Anti Static Dust Filter Bag to mitigate dust explosion hazards. When constructing a complete and efficient filtration system, our Anti-static Dust Collector Bags are the ideal component. For applications demanding superior fine dust capture and surface filtration, a PTFE Membrane Filter Bag can be laminated onto the fiberglass substrate. This combination offers the strength of fiberglass with the release properties of a membrane. In contrast, a Nonwoven fabric filter Bag is typically used for different applications where depth filtration is the primary mechanism.

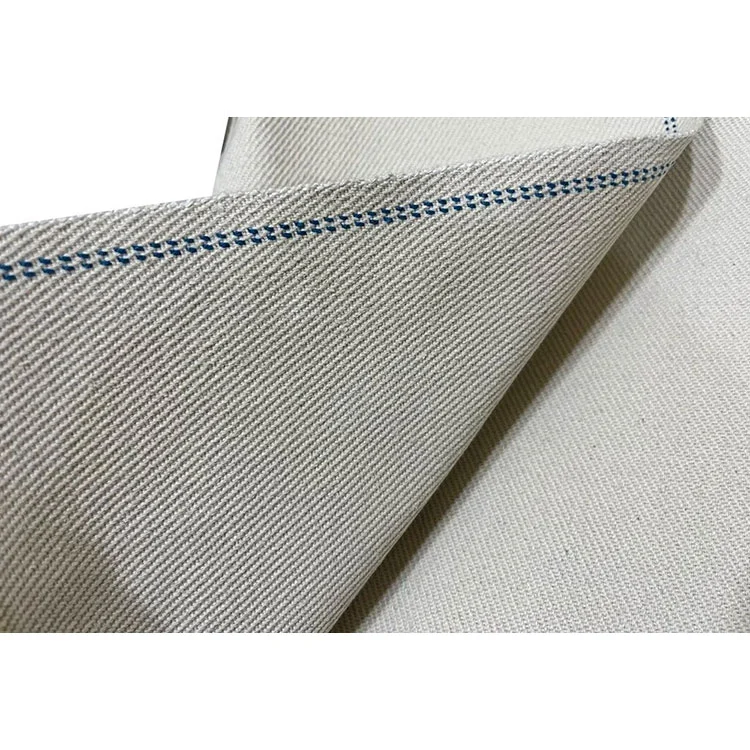

The Woven Fiberglass Filter Bag is engineered for longevity and reliability. Its construction from continuous filament fiberglass yarns, woven into a specific pattern, provides a robust filter media that resists stretching and distortion under high temperatures and fluctuating pressure conditions. This inherent stability ensures consistent filtration efficiency and a longer operational lifespan, reducing downtime and maintenance costs. The surface of the bag can be treated with various proprietary finishes, such as graphitic or silicone-based coatings, to enhance dust release properties and improve chemical resistance against acids and alkalis.

Key Technical Specifications of Woven Fiberglass Filter Bags

- Maximum Continuous Operating Temperature: 550°F (288°C)

- Peak Instantaneous Temperature: 600°F (316°C)

- Fabric Weight: Ranges from 14 oz/yd² to 45 oz/yd²

- Thread Count: Customizable weaves for specific airflow and efficiency requirements

- Finish: Available with Graf-A, Silicone, or Teflon B treatments

- Air Permeability: Typically 20 - 90 CFM/ft²

Performance Comparison Table

| Property | Standard Woven Fiberglass | With PTFE Membrane Lamination | With Silicone Coating |

|---|---|---|---|

| Filtration Efficiency | High (Surface Loading) | Very High (Surface Filtration) | High (Surface Loading) |

| Dust Cake Release | Good | Excellent | Very Good |

| Chemical Resistance | Excellent (except fluorides & strong alkalis) | Excellent | Enhanced Acid Resistance |

| Typical Pressure Drop | Medium | Low (after cake formation) | Medium |

| Primary Application | Cement, Asphalt, Metal Processing | Carbon Black, Pharmaceutical, Fine Chemicals | Incinerators, Boilers, Acidic Environments |

Common Weave Patterns and Characteristics

| Weave Pattern | Fabric Stability | Air Permeability | Surface Texture |

|---|---|---|---|

| Plain Weave | Excellent | Lower | Smooth |

| Twill Weave | Very Good | Medium | Diagonal Pattern |

| Satin Weave | Good | Higher | Very Smooth |

Hot Products

High-Performance Antistatic Filter Cloth

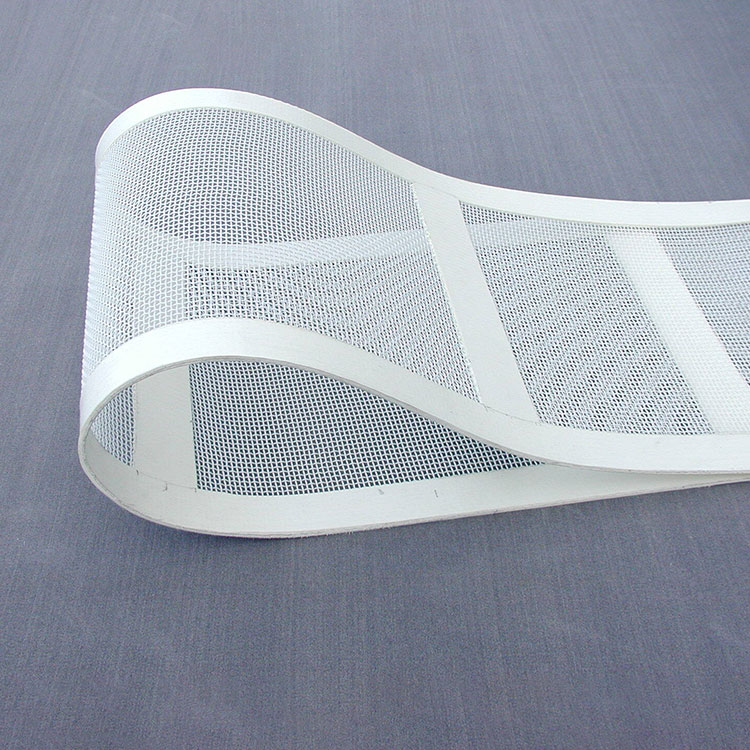

Our High-Performance Antistatic Filter Cloth is made with weft yarns that are completely made of antistatic fibre, so it's super effective at resisting static compared to standard filter fabrics. This Chinese supplier SMCC filter cloth is perfect for making fluid bed filter bags and is ideal for high-temperature applications in the pharmaceutical and food processing industries.Milk Filter Media

Qingdao Star Machine is wholesale of Milk Filter Media,the main material The material is usually polypropylene, polyester and nylon, The filter cloth of these two materials has the characteristics of high strength, wear resistance, high temperature resistance, corrosion resistance, easy cleaning, etc., which can meet the filtration needs of milk processing.Right Angle Electromagnetic Pulse Valve

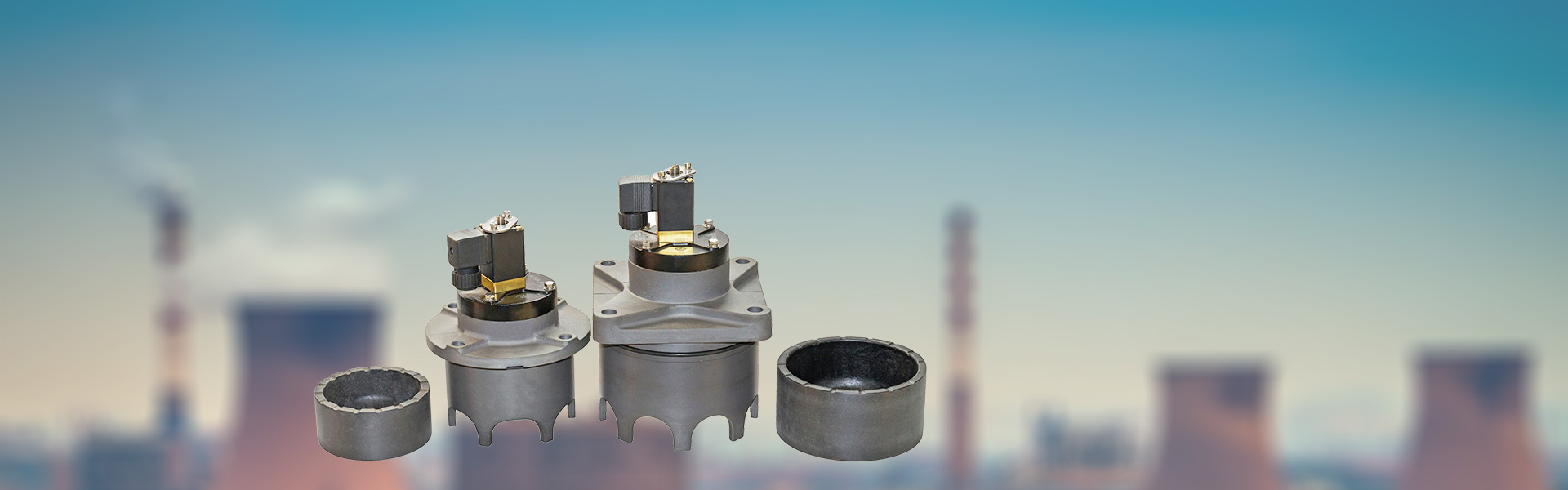

Qingdao Star Machine is Right Angle Electromagnetic Pulse Valve supplier with cheap price and top quality.It is divided into three categories: right Angle type, submerged type and straight through type. The air outlet and the air inlet are at a 90 degree Angle, so it is called a right Angle electromagnetic pulse valve.The electromagnetic pilot head of the right Angle electromagnetic pulse valve is generally driven by an electromagnet or double electronically controlled electromagnet, and the pulse blowing ash is realized through the switching pulse valve.Optipow105 Filter Plunger

Qingdao Star Machine's high quality Optipow105 Filter Plunger is important of the Optipow105 Pulse Jet Valve.A plunger that prevents impurities or particles from entering the system, usually in hydraulic or pneumatic transmission systems. These plungers usually have good wear and corrosion resistance, which can effectively protect the efficient operation of the entire system.Dust Filter Bag

Wholesale cheap price Dust Filter Bag from Qingdao Star Machine,it is a special filter bag for filtering mining dust, usually made of high-strength synthetic fiber materials, such as polyester fiber, polypropylene fiber and glass fiber. These materials are resistant to wear and tear and can effectively filter and capture particulate matter during mining processing.SCG353A043 Right Angle Valve

SCG353A043 right angle valve can totally replace the original ASCO pulse valve, it is a high quality replacement if you factory needs to change the pulse valves. Before we send them out, we check that all pulse valves are completely sealed to make sure there are no leaks.