Pulse Valve for Industry

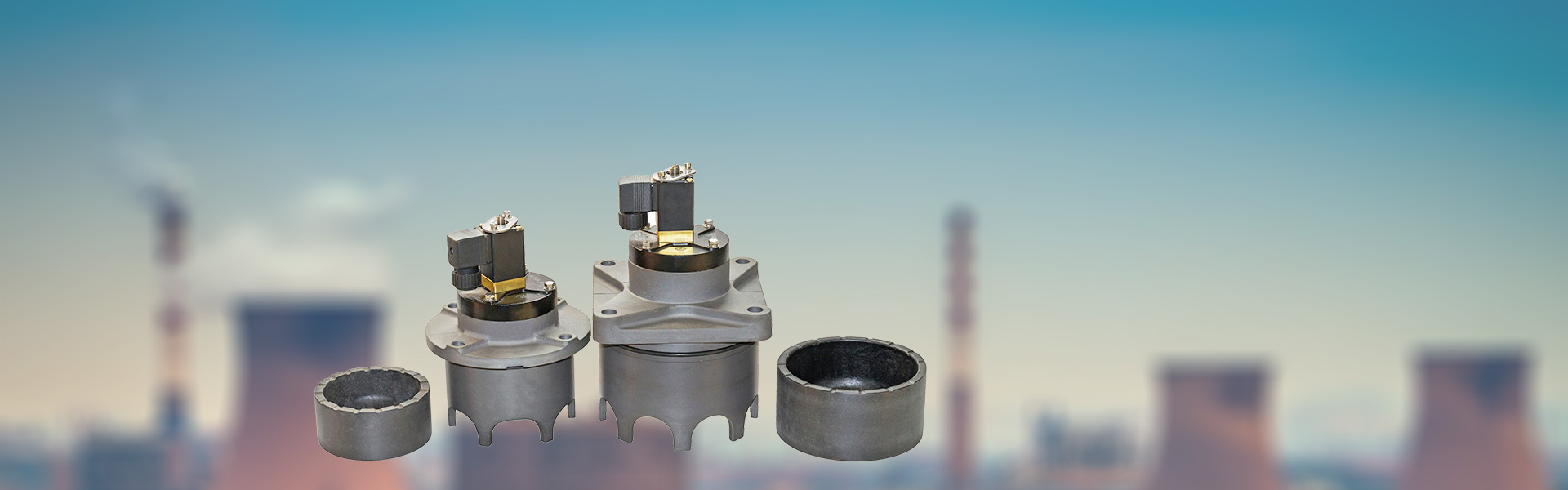

What is an Industrial Pulse Valve?

An industrial pulse valve is a critical component in dust collection systems. It operates by releasing short, high-pressure bursts of air (pulses) to clean filter bags or cartridges. This process dislodges accumulated dust, maintaining system efficiency and airflow. Designed for durability in harsh environments, these valves are essential for industries dealing with significant particulate matter, ensuring operational continuity and compliance with environmental regulations.

Key Features of Our High-Performance Pulse Valves

Our pulse valves are engineered for reliability, long service life, and maximum cleaning efficiency. They are constructed from high-grade materials to withstand demanding industrial conditions.

- Rugged Body Construction: Manufactured from precision-cast aluminum or stainless steel for excellent corrosion resistance and mechanical strength.

- High-Flow Diaphragm: A large, reinforced diaphragm ensures rapid valve action and consistent, powerful pulse delivery, even with fluctuating air pressure.

- Low Power Consumption: Efficient solenoid design minimizes energy usage, reducing operational costs.

- Easy Maintenance: Modular design allows for quick disassembly and replacement of internal components without removing the valve from the pipeline.

- Versatile Mounting: Compatible with standard pipe threads (e.g., NPT, BSP) for straightforward integration into existing dust collector designs.

Detailed Technical Specifications

Our pulse valves are available in multiple sizes to match various dust collector requirements. The following table outlines the standard specifications for our most popular models.

| Model Code | Orifice Diameter | Operating Pressure Range (PSI/Bar) | Voltage Options | Air Consumption per Pulse (Liters) | Thread Connection | Weight (kg) |

|---|---|---|---|---|---|---|

| PV-1 | 1 inch / 25 mm | 40 - 100 PSI / 2.8 - 7 Bar | 24V DC, 110V AC, 220V AC | 2.5 - 3.0 | 1" NPT | 1.2 |

| PV-1.5 | 1.5 inch / 38 mm | 40 - 100 PSI / 2.8 - 7 Bar | 24V DC, 110V AC, 220V AC | 5.0 - 6.5 | 1.5" NPT | 1.8 |

| PV-2 | 2 inch / 50 mm | 40 - 100 PSI / 2.8 - 7 Bar | 24V DC, 110V AC, 220V AC | 8.0 - 10.0 | 2" NPT | 2.5 |

| PV-3 | 3 inch / 75 mm | 40 - 100 PSI / 2.8 - 7 Bar | 110V AC, 220V AC | 18.0 - 22.0 | 3" NPT | 4.1 |

Material and Environmental Compatibility

The choice of material for a pulse valve is crucial for its performance and lifespan in specific industrial settings.

- Aluminum Alloy: Ideal for standard industrial environments with dry, non-corrosive air. It offers a excellent balance of strength and light weight.

- Stainless Steel (304/316): Recommended for harsh environments involving moisture, corrosive chemicals, or extreme temperatures. SS316 provides superior resistance to chlorides and acids.

Typical Applications Across Industries

Our pulse valves are deployed in a wide array of sectors where effective dust control is paramount.

- Metalworking: Capturing grinding dust, welding fumes, and metal powders.

- Woodworking: Collecting sawdust and wood chips from sanding, cutting, and milling operations.

- Pharmaceuticals: Controlling potent powder substances during processing and packaging.

- Food Processing: Managing flour, sugar, starch, and other food-grade dust to maintain hygiene and prevent explosions.

- Mining and Minerals: Handling large volumes of abrasive dust from crushing, screening, and conveying.

- Power Generation: Filtering fly ash from coal-fired boilers.

Installation and Maintenance Guidelines

Proper installation and routine maintenance are key to optimal valve performance.

- Installation: Ensure the valve is mounted vertically with the solenoid on top. The air supply must be clean, dry, and lubricated if specified. Use thread sealant appropriate for compressed air systems.

- Maintenance Checks: Periodically inspect the diaphragm for wear or tears. Check the solenoid coil for secure electrical connections and proper function. Listen for irregular hissing, which may indicate a leaking diaphragm or seal.

- Replacement Parts: We offer comprehensive kits containing diaphragms, springs, seals, and gaskets for easy servicing, minimizing system downtime.

Hot Products

RCA3D0 Solenoid Valve

RCA3D0 Solenoid Valve with Coil 1/8″ NPT, 24VDC Coil (screw/spade).Fabric Filter Air Cleaning Valve

Qingdao Star Machine's Fabric Filter Air Cleaning Valve (also known as Starmachinechina135) has excellent product quality and long-lasting performance. We are committed to making more contributions to this world. Our valves adhere to the concept of sustainable development and provide effective solutions for air purification in various application fields.Antistatic Dust Filter Bag

Antistatic dust filter bag is the key component of the dust removal system, choose the right specification can improve the efficiency and safety of dust removal. Our filter bag is of good quality, easy to use, long service life.Refuse Classification Filter Cloth

China Qingdao Star Machine is Refuse classification filter cloth supplier.that is a filter equipment used in the process of garbage sorting and treatment, mainly used in the field of industrial and urban waste treatment.

Refuse classification filter cloth is usually made of corrosion resistant, high temperature resistant, wear resistant materials, such as polyester fiber, polypropylene fiber, polyamide fiber and so on. Its structure is divided into single layer or multi-layer.Solid-Liquid Separation Filter Cloth

Qingdao Star Machine wholesale solid-liquid separation filter cloth mainly includes polyester filter cloth, polypropylene filter cloth, nylon filter cloth, and vinylon filter cloth. Material properties of filter cloth: acid and weak alkali resistance. Good wear resistance, corrosion resistance, and recovery, but poor conductivity. Polyester fibers generally have a temperature resistance of 130-150 ℃. In addition to the unique advantages of ordinary felt filter fabrics, this product also has excellent wear resistance and high cost-effectiveness, making it the most widely used type of felt filter media.G1 Threaded Pulse Valve

The Qingdao Star Machine G1 Threaded Pulse Valve has an advantages in supply, high quality, low price, fast quotation, short delivery time, and long warranty period.