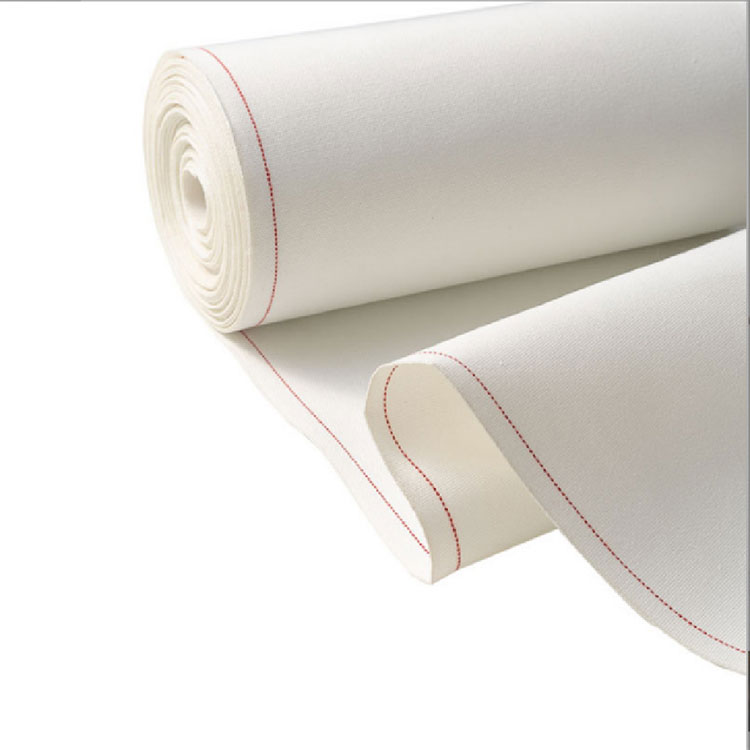

For industrial filtration applications, static electricity can pose a serious risk of fire and explosion. This is where specialized solutions like the Industrial Anti Static Dust Filter Bag are essential. Our flame retardant and antistatic dust filter bag is engineered to mitigate these hazards effectively. These Anti-static Dust Collector Bags are designed with advanced materials to ensure safety and longevity in demanding environments. The core filtration mechanism often incorporates a high-performance PTFE Membrane Filter Bag, which provides exceptional filtration efficiency and dust cake release. For applications requiring superior temperature resistance, the Woven Fiberglass Filter Bag material is integrated, offering robust performance in high-heat scenarios. Our product is the definitive choice for safeguarding operations where combustible dust is present.

The Flame Retardant Antistatic Dust Filter Bag is constructed to meet the most rigorous industry standards. Its multi-layered design ensures maximum particle capture while maintaining a low pressure drop, which enhances the overall efficiency of your dust collection system. The following list details its primary attributes and construction features:

- Inherently Flame Retardant Fabric Base: Prevents the propagation of flame and resists ignition.

- Integrated Conductive Yarns: Provides a continuous path for static electricity dissipation, ensuring an antistatic property.

- High-Temperature Stability: Suitable for continuous operation in environments up to 260°C (500°F).

- Excellent Chemical Resistance: Withstands exposure to a wide range of acids, alkalis, and solvents.

- Robust Seam Construction: Utilizes specialized stitching and sealing techniques to prevent seam failure and dust leakage.

For a detailed breakdown of the technical specifications, refer to the table below:

| Parameter | Specification / Value |

|---|---|

| Material Composition | Woven Fiberglass with PTFE Lamination & Integrated Conductive Fibers |

| Weight (GSM) | Approx. 750 g/m² |

| Filtration Efficiency | > 99.99% for particles ≥ 1 micron |

| Maximum Operating Temperature | 260°C (500°F) |

| Surface Resistivity | 10^4 - 10^6 Ω/sq (Antistatic Range) |

| Flame Retardancy Standard | Meets NFPA 701, EN ISO 15025 |

| Standard Sizes (Diameter x Length) | Ø 130mm x 1000mm, Ø 150mm x 2000mm, Ø 180mm x 2500mm (Custom sizes available) |

| Connection Type | Standard Snap-band, Crimped Top, or other custom fittings |

The Flame Retardant Antistatic Dust Filter Bag ensures operational safety by combining flame resistance with effective static charge control. Its construction is tailored for heavy-duty use in industries such as metalworking, chemical processing, pharmaceutical manufacturing, and woodworking, where dust explosion risks are a primary concern. Regular maintenance and proper installation are recommended to achieve the stated performance metrics and service life.